My wife and I have been traveling and it’s good to be back to the worktable. We did a camping road trip from Colorado to Orange County, California, to visit our youngest daughter and her family. As is our custom, we pulled our small travel trailer and visited many fabulous places going and coming back. This was our first time touring through the Southwest US, and we were amazed at the beauty of places we stayed – Zion National Park, Joshua Tree National Park and much more. The picture on the left is one of many places we visited on that trip – Zion National Park in Utah. Another trip took us north from Colorado. Can you guess? Pipe man Jack reached out to me about commissioning the next pipe on the worktable, a classy Pipe Pub Zulu. Jack wrote in his first email about his personal connection with Pipe Pub and his interest in The Pipe Steward:

Pipe man Jack reached out to me about commissioning the next pipe on the worktable, a classy Pipe Pub Zulu. Jack wrote in his first email about his personal connection with Pipe Pub and his interest in The Pipe Steward:

I would like to commission restoration on the #B3226 Pipe Pub. I wish to support your work in combating human and sex trafficking in Bulgaria and eastern Europe. There is a personal connection as well – I have Ukrainian family members and I am from Houston, the #1 city in the US for human trafficking. The tie-in with the Pipe Pub is that pipe was manufactured by a company that originally started in Houston. So, I feel restoration of this humble pipe is appropriate for the work you and your family are doing.

Since leaving Bulgaria in 2020, my wife and I have been working to help our churches in Ukraine during the unprovoked aggression of Russia. I asked Jack more about his Ukrainian connections and his response drilled down even further revealing more about Jack:

I’m not Ukrainian (as you’ve guessed) nor is my wife, but I have family who married a Ukrainian gentleman and one of the best souls I’ve met. Before and beyond the familial connection, I’ve always had an interest in the former Soviet countries and their post-Soviet progression. Ukraine captured my rapt attention with Euromaidan and the initial 2014 Russian invasion. Since Russia resumed kinetic action with their full-scale invasion in February 2022, I’ve been participating in Ukrainian aid efforts in any way I can. I had the fortune to attend the Ukraine Action Summit last fall. What an experience. I’d love to hear about your own experiences about living in Ukraine if you care to share. I’d like to go one day, maybe help with the rebuilding if possible.

One of my favorite questions I ask of all potential new stewards is how they came upon The Pipe Steward. Here was Jack’s reply:

Your articles on Rebornpipes were my initial introduction to The Pipe Steward. I was greatly impressed by the detail captured in your articles chronicling restorations and doubly so by the quality of your work and craftsmanship. Since I’m in my early 40’s, I am too young to have been around for the original Pipe Pub store. However, in an odd coincidence of life, I resided very close to one of the two descendant Pipe World stores when I lived in Austin for university. I didn’t smoke at the time, so I never went inside. They’re still open, so this means I’ll need to swing by the next time I visit!

I appreciated Jack’s words, and I also appreciated finding out that as a native Houstonian, he is employed in the oil industry and serves as a volunteer firefighter. Along with the Pipe Pub Zulu, Jack commissioned two other pipes which I’m looking forward to restoring, a Bertram Washington DC 30 Billard and a unique Comeaux Canadian USA 3-00 – pictured in that order: Here are pictures of the Pipe Pub Zulu that got Jack’s attention. All pipes restored help to benefit the Daughters of Bulgaria (now, Spring of Hope) – helping women and girls who have been trafficked and sexually exploited.

Here are pictures of the Pipe Pub Zulu that got Jack’s attention. All pipes restored help to benefit the Daughters of Bulgaria (now, Spring of Hope) – helping women and girls who have been trafficked and sexually exploited.

The nomenclature on the left side of the shank is clear and crisp: PIPE PUB. The right side is stamped: IMPORTED BRIAR. There are no markings that I can find on the stem.

The nomenclature on the left side of the shank is clear and crisp: PIPE PUB. The right side is stamped: IMPORTED BRIAR. There are no markings that I can find on the stem. I like working on Zulu shapes because to me they have a bit of attitude. I first was calling this pipe a Dublin, but I went back and forth trying to decide whether it was a Zulu/Woodstock/Yachtsman shape or it’s similar cousin, a Dublin. According to Bill Burney’s Pipedia’s Pipe Shapes Chart, the only difference with a straight up Dublin is that the Zulu has a gentle, 1/8 bent stem. Here is his description of this shape.

I like working on Zulu shapes because to me they have a bit of attitude. I first was calling this pipe a Dublin, but I went back and forth trying to decide whether it was a Zulu/Woodstock/Yachtsman shape or it’s similar cousin, a Dublin. According to Bill Burney’s Pipedia’s Pipe Shapes Chart, the only difference with a straight up Dublin is that the Zulu has a gentle, 1/8 bent stem. Here is his description of this shape. Our pipe has a slight bend and for this reason, I decided to lean toward the Zulu/Woodstock/Yachtsman – a pipe shape with many names!

Our pipe has a slight bend and for this reason, I decided to lean toward the Zulu/Woodstock/Yachtsman – a pipe shape with many names!

I enjoyed working on another Pipe Pub pipe a few years ago and since it was the first time working on a Pipe Pub, I drilled down on the research to learn more about the brand (Discovering the History of a Pipe Pub Brigade Made in London, England, Canadian Lumberman originally posted on Rebornpipes). When I dove into the research for the Pipe Pub Lumberman with a COM, ENGLAND, I thought most likely that this was a UK based brand yet there was no information about Pipe Pub on my regular information sites – Pipedia and Pipephil. Doing a general ‘Pipe Pub’ or ‘Pipe Pub Brigade’ search on the internet rendered links for bagpipers, bagpipe brigades, Irish pubs and pipes…, which did not help my research much! I reached out to Steve at Rebornpipes to tap his rich reservoir of knowledge and he said he had heard of ‘Pipe Pub’ and sent a link to a ‘Pipe Pub London Special’ – a pipe listing that had been on sale on SmokingPipes.com. It was Steve who suggested that the brand was perhaps made by special order for pipe shops and stores. This bit of speculation sent me back to Google not searching for a pipe brand but for a place. I repeat what I wrote in that original Pipe Pub research because it is rich with the input of pipemen closer to the origins of the name Pipe Pub which pipeman Jack is sure to appreciate with his personal connection to this name:

I went back to Google not looking for pipes but for places named ‘Pipe Pub.’ I hit pay dirt and the dirt was surprising! With the COM of the Canadian stamped indicating London, England, I had been expecting to find something that was UK based but instead, I found a reference for Pipe Pub that was based in the great US state of Texas – who would have thought? Through several iterations of search parameters, I came across a Google Group chat stream that started in 1998 entitled, “Pipe Pub?” . The question posed was about a Pipe Pub “almost Canadian” pipe that had the same nomenclature and stem ‘PP’ as mine, but the COM was stamped, ‘Italy’. The questioner in the stream proposed a correlation with the Italian Savinelli name wondering if Pipe Pub might be a second of that well-known Italian pipe house?

The next response to Bro. R from Larry introduced the Texas connection:

Bro. R,

Back in the 70’s the mall tobacconists here in Austin, TX, were named Pipe Pub; they became Pipe World a little later. I don’t know if, then or now, these businesses were strictly local or part of a larger chain. I’m pretty sure they sold a store brand with their name on the pipes. Today, Pipe World’s store brand pipes *are* made by Savinelli.

Larry

With these two entries, I knew that we were talking about the same pipe name – the ‘PP’ on the stem was the clincher. Pipe Pub is a local Texas tobacconist which had pipes manufactured with the Pipe Pub name. But there was more information that perhaps should be submitted to Pipedia! The next entry I’m including in its entirety because it brings in much of the historical context with much color and the source of the information is a Jon Carter, who is described by Don Schram as a manager of Pipe Pub in the 80s:

Here’s the skinny on Pipe Pub, as related to me by Jon Carter, former manager of Pipe Pub from 1983 to 1987, who isn’t online as of yet. (Messages will be relayed to him through me at: dsc…@bigfoot.com ,however.)

Pipe Pub was started in the Houston area of Texas in the early 70’s with a single downtown store. It was joined a short time later by a store located in the Austin, TX, area, which was owned and operated by a brother-in-law of the original founders (whose name escapes Jon for the moment). While Pipe Pub wasn’t nationwide, they owned approx. 14 stores throughout Texas, primarily in the Houston area, and were much in competition with Tinderbox. (Comparable to Churchill’s in the S.E. Michigan area.)

The Pipe Pub pipe in question was confirmed by Jon to be a pipe from this chain. The letters ‘PP’ in script on the stem indicate that the bit is original, and you are correct in that it stands for Pipe Pub. As far as the age, there is no definite method of dating this pipe, however; Pipe Pub only carried their own line of ‘Private Label’ pipes between the early 70’s and 1983 when they were phased out in favor of higher grade (and higher priced) pipes, to coincide with the Texas oil boom of the 80’s. Jon was not able to confirm positively that the pipe is indeed of Savinelli make (second or otherwise), however, he did point out that Pipe Pub did have an excellent relationship with the Savinelli company, as they were allowed to carry and sell the rare Savinelli 0000 (Quadruple-ought) Autograph, of which only 3 have been produced in the last century. Jon also pointed out that he and another manager sold it to a gentleman who worked for the telephone company to complete a collection of Savinelli Autographs. (He went to the bank and took out a $5000 loan for it. The bank initially thought he was purchasing ‘oil drilling pipe’, but gave him a personal loan for the tobacco pipe anyways. He kept it in a lock box for a while, then finally broke it out and smoked it for the first time during the 1986 or 1987 Superbowl.)

To round out the history of Pipe Pub, the chain was bought out, save one store, in 1985 by a family, by name of Kowalski, who turned the tobacco chain into a chain of mall knick-knack stores. (Sound all-too familiar Churchill’s customers?) The one store, Pipe Pub in Austin, run by the brother-in-law, was not included in the deal, but it was agreed that he would change the name of the store. Jon commented that the lone store may have changed it’s name to Pipe World, but wasn’t really privy to such information, as it was, more or less, operated as a renegade store. The Kowalski’s opened one additional store in Louisiana, their home state, and promptly ran the chain right into the ground after one Christmas season, due to poor ownership and product focus. Jon pointed out, “They carried vibrating pillows, for God’s sake!” Forcing the company into bankruptcy, the Kowalski’s sold the chain back to the original owners, whom to his knowledge, still own it today.

For more information, Jon recommends calling down to Houston and asking information for their main office, which was on Mitchelldale. [A search of Yahoo Yellow Pages came up empty, however there is a Carol’s Pipe Pub in Bacliff, TX, a suburb of Houston. Phone (281) 488-7300. It’s unknown if they’re related.] DS. (Don Schram.)

This information-filled post is dated, 1998. On a hunch, I google the name of the offshoot store characterized as the ‘renegade’ store that wasn’t part of the reported 1985 Pipe Pub acquisition described in stream above. As part of the legal agreement this store was required to change the name without further association with the Pipe Pub name. Pipe World, based in Austin, and run by a “brother-in-law” family member came into existence – or, more accurately, carried on the original legacy of Pipe Pub under a different name because it seems that the new owners of Pipe World ran the company off the rails. I found http://pipeworld.com/ with different locations in Texas and wondered if this was the same ‘Pipe World’ referenced above.

This information-filled post is dated, 1998. On a hunch, I google the name of the offshoot store characterized as the ‘renegade’ store that wasn’t part of the reported 1985 Pipe Pub acquisition described in stream above. As part of the legal agreement this store was required to change the name without further association with the Pipe Pub name. Pipe World, based in Austin, and run by a “brother-in-law” family member came into existence – or, more accurately, carried on the original legacy of Pipe Pub under a different name because it seems that the new owners of Pipe World ran the company off the rails. I found http://pipeworld.com/ with different locations in Texas and wondered if this was the same ‘Pipe World’ referenced above.

As I’ve done in the past with surprising success, I go directly to the front door and knock. I went to the ‘Contact Us’ section on the Pipe World site and sent an email asking if anyone had been around long enough to know something about the history of the former Pipe Pub Tobacconist out of which Pipe World came. You never know what will happen!

I received a reply to my email the same day from Pipe World – from Kyle who asked me to call directly if I had any questions. Thankfully, I have an internet phone from Bulgaria, and I called Kyle in Texas. Kyle answered the phone and was extremely helpful. His grasp of the history was amazing – he had been there during the whole transition. I was totally taken off guard when I discovered through our conversation that he was the owner of Pipe World. His name is Kyle Haass. He was the ‘brother-in-law’ referenced above who opened the new Pipe World and held firm to the values that had been true historically of Pipe Pub.

I received a reply to my email the same day from Pipe World – from Kyle who asked me to call directly if I had any questions. Thankfully, I have an internet phone from Bulgaria, and I called Kyle in Texas. Kyle answered the phone and was extremely helpful. His grasp of the history was amazing – he had been there during the whole transition. I was totally taken off guard when I discovered through our conversation that he was the owner of Pipe World. His name is Kyle Haass. He was the ‘brother-in-law’ referenced above who opened the new Pipe World and held firm to the values that had been true historically of Pipe Pub.

I enjoyed talking with Kyle, his recall of the events and his grasp of all the many moving parts of the tobacco industry fascinated me. He was able to answer the primary question I had about the origin of the Pipe Pub pipes. Definitively according to Kyle, during the 70s and early 80s, GBD/Comoy’s was producing the English line of pipes with the Pipe Pub name out of the London factory. Pipe Pub pipes marked ITALY were all produced by the well-known Italian house of Savinelli. He said that he doubted that Savinelli continued to do sub-contract work because they sell enough of their own pipes today to make it worthwhile. He said that they had to order a lot of each shape as part of the requirements – I believe he said that they introduced a new shape each year. He mentioned that the pipes that were produced in England and Italy with the Pipe Pub label were done with higher quality in mind. I said that I could attest to this as I looked at the GBD/Comoy’s factory made Pipe Pub Canadian on my worktable.

After talking about the current climate in the tobacco industry, some of the current issues with Dunhill and the like, I shared with him our work with the Daughters of Bulgaria (he was surprised to hear I was calling from Bulgaria!) and my love for restoring classic pipes which benefit our Daughters of Bulgaria Foundation. We ended our conversation with words of friendship and for me, a desire to stop off at Pipe World and visit Kyle at their shops in Round Rock and Austin, Texas. I appreciated the time Kyle gave me on the telephone to discover a bit more pipe history.

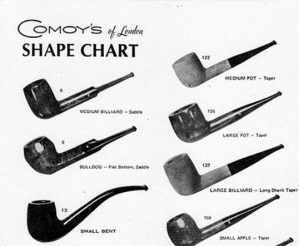

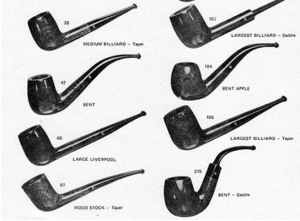

I’ve repeated this from the earlier post because it is rich to find someone with firsthand knowledge about a brand, label or company history. Talking with Kyle helped a great deal to put the ‘Pipe Pub’ puzzle together. Based upon my conversation with Kyle and the earlier threads, the ‘Pipe Pub’ private labeling spanned the early 1970s until 1983 when they phased out the shop’s ‘special label’ pipes for higher quality pipes. The other interesting bit of information is that there were two manufacturers of pipes stamped with ‘Pipe Pub’ – GBD/Comoy’s for the English line and Savinelli for those stamped with the Italy COM. For our Zulu, we do not have a specific COM stamping, nor do we have a shape number. However, I feel confident and not too much of a stretch to assume that if the pipe was made by Savinelli, it would more likely have a definite Italy stamping on it. Whereas, with those produced in London, maybe not as concerned with the ‘LONDON” COM since they were made for US distribution. I would guess that this Zulu was made by Comoy’s for US distribution in the 70s. The chart below is Circa 1975 (Pre-Cadogan) Shape Chart, courtesy Doug Valitchka (Comoy’s Shape Number Chart – Pipedia) which shows a very similar shape likeness on the first column, last pipe – ‘Wood Stock Taper’.

With a renewed appreciation for the Texas-based Pipe Pub on the worktable, it’s time to take a closer look at the condition of the pipe itself. I like the feel of this pipe – it cradles nicely and is light. The chamber has some cake build up which will be removed along with lava flow crusted over the rim.

With a renewed appreciation for the Texas-based Pipe Pub on the worktable, it’s time to take a closer look at the condition of the pipe itself. I like the feel of this pipe – it cradles nicely and is light. The chamber has some cake build up which will be removed along with lava flow crusted over the rim. The rim edge has several nicks and dents which need addressing.

The rim edge has several nicks and dents which need addressing. The briar surface is dark with grime with a few dents and small fills that need checking after the stummel has been cleaned.

The briar surface is dark with grime with a few dents and small fills that need checking after the stummel has been cleaned. The slightly bent stem shows subtle oxidation. The bit has been chewed pretty good – both the bit and button have tooth bites and compressions – upper and lower. Restoring the stem will be a challenge!

The slightly bent stem shows subtle oxidation. The bit has been chewed pretty good – both the bit and button have tooth bites and compressions – upper and lower. Restoring the stem will be a challenge! To begin the restoration process, the stem airway is cleaned with pipe cleaners moistened with isopropyl 99%.

To begin the restoration process, the stem airway is cleaned with pipe cleaners moistened with isopropyl 99%. To address oxidation, the stem is placed into a soak of Briarville.com’s ‘Pipe Stem Oxidation Remover’. The stem will soak for several hours.

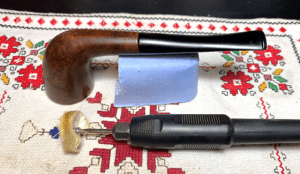

To address oxidation, the stem is placed into a soak of Briarville.com’s ‘Pipe Stem Oxidation Remover’. The stem will soak for several hours. Turning next to the stummel, the first step in the general cleaning process is to clean the chamber of carbon cake build up to allow a fresh cake to be created and to inspect the condition of the briar. To do this, the Kleen Reem Pipe Tool is used. This tool is used instead of the usual Pipnet Tool because the Zulu’s chamber is more severely tapered in a conical manner. The chamber tapering toward the floor is better addressed using the older Kleen Reem Tool with the expanding cutting arms that can snug-up to the chamber wall more easily.

Turning next to the stummel, the first step in the general cleaning process is to clean the chamber of carbon cake build up to allow a fresh cake to be created and to inspect the condition of the briar. To do this, the Kleen Reem Pipe Tool is used. This tool is used instead of the usual Pipnet Tool because the Zulu’s chamber is more severely tapered in a conical manner. The chamber tapering toward the floor is better addressed using the older Kleen Reem Tool with the expanding cutting arms that can snug-up to the chamber wall more easily. After the reaming, the chamber wall is scraped with the Savinelli Fitsall Tool which does a good job of getting at the angles at the floor of the chamber.

After the reaming, the chamber wall is scraped with the Savinelli Fitsall Tool which does a good job of getting at the angles at the floor of the chamber. The final step is to sand the chamber using 220 grit paper wrapped around a dowel. All the tools are pictured below.

The final step is to sand the chamber using 220 grit paper wrapped around a dowel. All the tools are pictured below. A quick inspection of the chamber reveals no heating issues. Healthy briar ready to go again!

A quick inspection of the chamber reveals no heating issues. Healthy briar ready to go again! With the reaming completed, the cleaning expands to the exterior briar. A few starting pictures show the dark briar surface which has a bit of grime on it.

With the reaming completed, the cleaning expands to the exterior briar. A few starting pictures show the dark briar surface which has a bit of grime on it.

To clean the surface, undiluted Murphy’s Oil Soap is used with a cotton pad to scrub the surface.

To clean the surface, undiluted Murphy’s Oil Soap is used with a cotton pad to scrub the surface. To address the lava flow over the rim, a brass brush helps by adding some muscle to the cleaning without impacting the briar.

To address the lava flow over the rim, a brass brush helps by adding some muscle to the cleaning without impacting the briar. After the scrubbing at the worktable, the stummel is taken to the utility sink. Warm water is used with anti-oil, liquid dishwashing soap, and the internals are scrubbed with shank brushes. After a good cleaning, the stummel is rinsed thoroughly and brought back to the worktable.

After the scrubbing at the worktable, the stummel is taken to the utility sink. Warm water is used with anti-oil, liquid dishwashing soap, and the internals are scrubbed with shank brushes. After a good cleaning, the stummel is rinsed thoroughly and brought back to the worktable.

Cleaning the internals continue with cotton buds, pipe cleaners and isopropyl 99% alcohol. Scraping the chamber walls with a small dental spoon helps to excavate the tars and oils from the chamber walls which allows fewer cotton buds to be sacrificed!

Cleaning the internals continue with cotton buds, pipe cleaners and isopropyl 99% alcohol. Scraping the chamber walls with a small dental spoon helps to excavate the tars and oils from the chamber walls which allows fewer cotton buds to be sacrificed! After the buds start emerging lighter, I call the internal cleaning complete for now. Later, I will give the stummel a kosher salt and alcohol soak to make sure the internals are clean, ‘ghostless’, fresh and ready for a new steward.

After the buds start emerging lighter, I call the internal cleaning complete for now. Later, I will give the stummel a kosher salt and alcohol soak to make sure the internals are clean, ‘ghostless’, fresh and ready for a new steward. With the cleaning completed for now, I look at the briar surface and I like what I see. The briar grain has a deep, dark patina which is nice. The main issue at this point is the condition of the rim. It cleaned up nicely, but the inner chamber rim has a dark ring from charring and some darkened briar on the aft of the rim from lighting practices.

With the cleaning completed for now, I look at the briar surface and I like what I see. The briar grain has a deep, dark patina which is nice. The main issue at this point is the condition of the rim. It cleaned up nicely, but the inner chamber rim has a dark ring from charring and some darkened briar on the aft of the rim from lighting practices. The outer edge of the rim also has a myriad of nicks, cuts and dents.

The outer edge of the rim also has a myriad of nicks, cuts and dents. To address these rim issues, the topping board will be used. With a piece of 220 grit paper on the board, the stummel is inverted and rotated several times to sand the rim evenly. Only as much topping will be needed as to remove the imperfections and clean the rim up.

To address these rim issues, the topping board will be used. With a piece of 220 grit paper on the board, the stummel is inverted and rotated several times to sand the rim evenly. Only as much topping will be needed as to remove the imperfections and clean the rim up. After the first set of rotations, enough briar has been removed with the 220 grit paper.

After the first set of rotations, enough briar has been removed with the 220 grit paper. The 220 grit paper is followed by 320 grit paper and several more rotations.

The 220 grit paper is followed by 320 grit paper and several more rotations. Finally, the finer 600 grit paper is placed on the board with more rotations.

Finally, the finer 600 grit paper is placed on the board with more rotations. The skin on the back of the rim still has some rough briar to remove. I decided to strategically sand this spot rather than continue taking briar off the entire rim.

The skin on the back of the rim still has some rough briar to remove. I decided to strategically sand this spot rather than continue taking briar off the entire rim. After sanding the spot with 320 and 600 grit papers, there’s only a dimple remaining which should blend in after all the sanding and polishing.

After sanding the spot with 320 and 600 grit papers, there’s only a dimple remaining which should blend in after all the sanding and polishing. I noted a dent on the heel of the stummel earlier. It would take aggressive sanding to remove the dent which I do not want to do.

I noted a dent on the heel of the stummel earlier. It would take aggressive sanding to remove the dent which I do not want to do. Instead of sanding, the steaming method will be used to minimize the dent. The cloth is wet and using an iron, the hot iron presses the wet cloth against the dent causing the water to steam. The steam is forced into the wood surface and the moisture helps to expand briar to its original form. Wood is microscopically porous like a sponge absorbing the moisture.

Instead of sanding, the steaming method will be used to minimize the dent. The cloth is wet and using an iron, the hot iron presses the wet cloth against the dent causing the water to steam. The steam is forced into the wood surface and the moisture helps to expand briar to its original form. Wood is microscopically porous like a sponge absorbing the moisture. After a few rounds of the steaming, the dent has minimized. There is still a mark but there is no indentation with the touch.

After a few rounds of the steaming, the dent has minimized. There is still a mark but there is no indentation with the touch. To clean the surface gently and remove minor scratches, finer sanding sponges are used – medium, light and fine grades. I do not want to remove the rich finish.

To clean the surface gently and remove minor scratches, finer sanding sponges are used – medium, light and fine grades. I do not want to remove the rich finish. With the hour growing late, before turning the light off, the internal cleaning of the stummel is continued with a kosher salt and isopropyl 99% grade alcohol soak. The first step is to pull and twist a cotton ball to form a wick. The wick serves to help draw the tars and oils from the internal briar.

With the hour growing late, before turning the light off, the internal cleaning of the stummel is continued with a kosher salt and isopropyl 99% grade alcohol soak. The first step is to pull and twist a cotton ball to form a wick. The wick serves to help draw the tars and oils from the internal briar. Using the stiff wire, the cotton wick is guided up the mortise through the draft hole. No salt will enter the internals of the stummel.

Using the stiff wire, the cotton wick is guided up the mortise through the draft hole. No salt will enter the internals of the stummel. Next, kosher salt fills the chamber. Kosher salt is used because, unlike regular iodized table salt, it leaves no aftertaste leaving the chamber fresh and clean. The stummel is situated in the egg crate to keep it steady and to place the rim and the end of the shank parallel.

Next, kosher salt fills the chamber. Kosher salt is used because, unlike regular iodized table salt, it leaves no aftertaste leaving the chamber fresh and clean. The stummel is situated in the egg crate to keep it steady and to place the rim and the end of the shank parallel. Using the large eye dropper, isopropyl 99% fills the chamber until it surfaces over the salt. After a while, the alcohol is absorbed into the stummel, and the alcohol is again topped off. The stummel will soak through the night.

Using the large eye dropper, isopropyl 99% fills the chamber until it surfaces over the salt. After a while, the alcohol is absorbed into the stummel, and the alcohol is again topped off. The stummel will soak through the night. The new day awoke to rain in Colorado. The soak through the night did the job. The picture shows the soiling in the salt and the cotton wick from drawing the tars and oils from the briar.

The new day awoke to rain in Colorado. The soak through the night did the job. The picture shows the soiling in the salt and the cotton wick from drawing the tars and oils from the briar. A single cotton bud and pipe cleaner confirm the internals are clean. The whiff test also is good 😊.

A single cotton bud and pipe cleaner confirm the internals are clean. The whiff test also is good 😊. After topping the stummel, the dark finish was removed by the sanding so that the rim is much lighter than the stummel finish. The rim needs to be colored to blend with the rest of the stummel.

After topping the stummel, the dark finish was removed by the sanding so that the rim is much lighter than the stummel finish. The rim needs to be colored to blend with the rest of the stummel. The question in my mind as I seek to choose a dye stick to match the stummel hue is the grain. The stummel appears to have had a very dark, probably black dye undercoat which creates the dark grain lines. After deliberation, I decided to use a walnut dye stick. The results look pretty good.

The question in my mind as I seek to choose a dye stick to match the stummel hue is the grain. The stummel appears to have had a very dark, probably black dye undercoat which creates the dark grain lines. After deliberation, I decided to use a walnut dye stick. The results look pretty good. The next step is to apply the full set of 9 micromesh pads to the stummel. Between each pad, the stummel is wiped with a moist cloth to remove the dust and improve the traction for the next pad. The first 3 pads used are 1500, 1800, and 2400 grades.

The next step is to apply the full set of 9 micromesh pads to the stummel. Between each pad, the stummel is wiped with a moist cloth to remove the dust and improve the traction for the next pad. The first 3 pads used are 1500, 1800, and 2400 grades. After the first set of three pads, I was dissatisfied with what I was seeing as I looked at the rim. The micromesh sanding really brought out the dark grain lines on the stummel – beautiful grain patterns as you can see above. Unfortunately, I missed a few picture opportunities so the written word will need to suffice. The walnut dye on the rim matched nicely with the general hue, BUT the grain on the rim was noticeably less distinctive compared to the rest of the stummel. This is not pictured. What I did next was to test a bit of black dye stick on the rim and sand it off with fine 320 paper. The black dye was absorbed by the grain as I had hoped resulting in lines being more distinct. Black dye was then applied to the entire rim. The following picture picks up after sanding the first round of black dye and then applying another for good measure.

After the first set of three pads, I was dissatisfied with what I was seeing as I looked at the rim. The micromesh sanding really brought out the dark grain lines on the stummel – beautiful grain patterns as you can see above. Unfortunately, I missed a few picture opportunities so the written word will need to suffice. The walnut dye on the rim matched nicely with the general hue, BUT the grain on the rim was noticeably less distinctive compared to the rest of the stummel. This is not pictured. What I did next was to test a bit of black dye stick on the rim and sand it off with fine 320 paper. The black dye was absorbed by the grain as I had hoped resulting in lines being more distinct. Black dye was then applied to the entire rim. The following picture picks up after sanding the first round of black dye and then applying another for good measure. The next two pictures show the progress with lightly sanding the rim with fine 320 grit paper to give the grain more pop.

The next two pictures show the progress with lightly sanding the rim with fine 320 grit paper to give the grain more pop. After sanding sufficiently, the dark Noce Medio (which I bought in Bulgaria!) or medium walnut was applied to the rim to bring the general hue into alignment with the stummel. I like what I see.

After sanding sufficiently, the dark Noce Medio (which I bought in Bulgaria!) or medium walnut was applied to the rim to bring the general hue into alignment with the stummel. I like what I see. Finally, the rim again receives the first three micromesh pads and Walla! So, so much more expressive and distinctive is the rim grain now compared to what it was before. Nice.

Finally, the rim again receives the first three micromesh pads and Walla! So, so much more expressive and distinctive is the rim grain now compared to what it was before. Nice. Continuing next with the second set of micromesh pads, 3200, 3600, and 4000 grades are used. The lower picture shows how the rim is shaping up.

Continuing next with the second set of micromesh pads, 3200, 3600, and 4000 grades are used. The lower picture shows how the rim is shaping up. The final 3 pads are pads 6000, 8000 and 12000 grades.One more project needs attention before transitioning to the stem.

The final 3 pads are pads 6000, 8000 and 12000 grades.One more project needs attention before transitioning to the stem. Mark Hoover’s ‘Before & After’ Restoration Balm is a great product that helps to enrich the briar as well as bring out the rich natural hues of the briar. Placing a small amount on the finger, the Balm is worked into the briar. When it’s thoroughly worked in, the stummel is set aside for about 10 minutes for the Balm to be absorbed.

Mark Hoover’s ‘Before & After’ Restoration Balm is a great product that helps to enrich the briar as well as bring out the rich natural hues of the briar. Placing a small amount on the finger, the Balm is worked into the briar. When it’s thoroughly worked in, the stummel is set aside for about 10 minutes for the Balm to be absorbed. With excess Balm on the fingers, I always look to a needy pipe in my own collection that could take advantage of the ‘crumbs’ that fell off the table. This time around, this beautiful, diminutive Danish Scandia was the benefactor of some Balm.

With excess Balm on the fingers, I always look to a needy pipe in my own collection that could take advantage of the ‘crumbs’ that fell off the table. This time around, this beautiful, diminutive Danish Scandia was the benefactor of some Balm. After the time elapsed, a dedicated microfiber cloth is used to wipe away excess Balm and buff up the shine. I like the dark finish grain on this Zulu. Lots of horizontal pattern and the culminating bird’s eye patterns as well.

After the time elapsed, a dedicated microfiber cloth is used to wipe away excess Balm and buff up the shine. I like the dark finish grain on this Zulu. Lots of horizontal pattern and the culminating bird’s eye patterns as well. The stem soaked through the night in Briarville’s Pipe Stem Oxidation Remover and after fishing the stem out, the picture gives a good idea of what raised oxidation looks like on a vulcanite stem.

The stem soaked through the night in Briarville’s Pipe Stem Oxidation Remover and after fishing the stem out, the picture gives a good idea of what raised oxidation looks like on a vulcanite stem. A cloth is used to rub the surface vigorously to remove the oxidation. Some 0000 grade steel wool was also used to clear away some more stubborn parts. To remove the oxidation remover fluid from the airway, a few pipe cleaners and isopropyl 99% alcohol do the job.

A cloth is used to rub the surface vigorously to remove the oxidation. Some 0000 grade steel wool was also used to clear away some more stubborn parts. To remove the oxidation remover fluid from the airway, a few pipe cleaners and isopropyl 99% alcohol do the job. Looking now more closely at the bit, wow!, we have some issues. There is little doubt in my mind that the former steward loved this Zulu and used him as a ‘hands free’ favorite, enjoying a bowl while working at the desk or workbench. The button was clenched by the back molars it appears, and the scissor teeth did a job further up the stem shaft. The second picture shows the compressed button.

Looking now more closely at the bit, wow!, we have some issues. There is little doubt in my mind that the former steward loved this Zulu and used him as a ‘hands free’ favorite, enjoying a bowl while working at the desk or workbench. The button was clenched by the back molars it appears, and the scissor teeth did a job further up the stem shaft. The second picture shows the compressed button. The lower bit has the same story. Not as many compressions but much deeper. The button also shows the clenching.

The lower bit has the same story. Not as many compressions but much deeper. The button also shows the clenching. At this point, using the heating method is an attempt to minimize the damage. Using a Bic lighter, the flame paints the bit/button and heats the vulcanite rubber. The physics of the rubber naturally expands when heated and this expansion can help to minimize the compressions. So, one can only hope. After heating the upper and lower bit, the results are shown in these before and after photos. For the upper bit, the heating did minimize the compressions to a degree. One of the compressions (on the top of the photo) should be erased simply by sanding. The others still need to be patched. The button rounded up some but still needs to be addressed.

At this point, using the heating method is an attempt to minimize the damage. Using a Bic lighter, the flame paints the bit/button and heats the vulcanite rubber. The physics of the rubber naturally expands when heated and this expansion can help to minimize the compressions. So, one can only hope. After heating the upper and lower bit, the results are shown in these before and after photos. For the upper bit, the heating did minimize the compressions to a degree. One of the compressions (on the top of the photo) should be erased simply by sanding. The others still need to be patched. The button rounded up some but still needs to be addressed. There was a very distinctive change in the huge bite on the lower bit and the smaller compression above it was all but erased. The button still needs attention.

There was a very distinctive change in the huge bite on the lower bit and the smaller compression above it was all but erased. The button still needs attention. Before beginning the repair work on the bit, the area is cleaned with alcohol.

Before beginning the repair work on the bit, the area is cleaned with alcohol. Using Black Medium-Thick CA glue, both larger compressions on the upper bit are filled. The button lip also receives a layer of Black CA glue. To hold the patches in place and to quicken the curing time, an accelerator is used. For this kind of patch, that bears no weight and is primarily cosmetic, I usually use an accelerator. For patches that need strength, I usually allow the patch to cure at its own rate.

Using Black Medium-Thick CA glue, both larger compressions on the upper bit are filled. The button lip also receives a layer of Black CA glue. To hold the patches in place and to quicken the curing time, an accelerator is used. For this kind of patch, that bears no weight and is primarily cosmetic, I usually use an accelerator. For patches that need strength, I usually allow the patch to cure at its own rate. The same is done for the lower bit.

The same is done for the lower bit. After the patches cure thoroughly, a flat and squared needle file go to work on filing the patches down flush with the vulcanite surface. Shaping is also done on the button lip.

After the patches cure thoroughly, a flat and squared needle file go to work on filing the patches down flush with the vulcanite surface. Shaping is also done on the button lip. The final view of the upper bit filing.

The final view of the upper bit filing. The process is the same for the lower bit with the lip also being shaped and the hang ledge being refreshed.

The process is the same for the lower bit with the lip also being shaped and the hang ledge being refreshed. The filing transitions to sanding the upper and lower bit with 220 grit paper.

The filing transitions to sanding the upper and lower bit with 220 grit paper. The sanding expands to the entire stem using the finer 320 grit paper. To avoid shouldering on the shank facing, a plastic disk is used to guard the edge.

The sanding expands to the entire stem using the finer 320 grit paper. To avoid shouldering on the shank facing, a plastic disk is used to guard the edge. Next, the stem is wet sanded using 600 grit paper followed by applying 0000 grade steel wool.

Next, the stem is wet sanded using 600 grit paper followed by applying 0000 grade steel wool. Micromesh pads transform from sanding into polishing the vulcanite. Between each pad, Obsidian Oil is applied to the stem to condition the vulcanite and to protect it from oxidation. The first pads are 1500 to 2400, then 3200 to 4000, finishing with 6000 to 12000.

Micromesh pads transform from sanding into polishing the vulcanite. Between each pad, Obsidian Oil is applied to the stem to condition the vulcanite and to protect it from oxidation. The first pads are 1500 to 2400, then 3200 to 4000, finishing with 6000 to 12000.

The stem has certainly taken a turn for the better. To further condition and polish the vulcanite, Mark Hoover’s ‘Before & After’ Fine and Extra Fine Polish does a good job. Starting with a small amount of the Fine Polish on a finger, the polish is rubbed and worked into the vulcanite surface. After a few minutes working it in, the excess is wiped off with a paper towel. The Extra Fine Polish is applied and worked in in the same manner. Finally, the stem is wiped with a paper towel. The stem looks great!

The stem has certainly taken a turn for the better. To further condition and polish the vulcanite, Mark Hoover’s ‘Before & After’ Fine and Extra Fine Polish does a good job. Starting with a small amount of the Fine Polish on a finger, the polish is rubbed and worked into the vulcanite surface. After a few minutes working it in, the excess is wiped off with a paper towel. The Extra Fine Polish is applied and worked in in the same manner. Finally, the stem is wiped with a paper towel. The stem looks great! Now the home stretch. With the stem and stummel reunited, Blue Diamond compound is applied to the entire pipe. A dedicated cotton cloth buffing wheel is mounted on the rotary tool with the speed set at about 40% full power.

Now the home stretch. With the stem and stummel reunited, Blue Diamond compound is applied to the entire pipe. A dedicated cotton cloth buffing wheel is mounted on the rotary tool with the speed set at about 40% full power. To remove the compound dust that accumulates on the surface, a felt cloth is used.

To remove the compound dust that accumulates on the surface, a felt cloth is used. Finally, with another dedicated cotton cloth buffing wheel mounted at the same speed, carnauba wax is applied to the pipe. Following the application of wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine.

Finally, with another dedicated cotton cloth buffing wheel mounted at the same speed, carnauba wax is applied to the pipe. Following the application of wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine. This 1970s/early 80s survivor of the Pipe Pub ‘Personal Label’ production was most likely produced in London by Comoy’s. It was produced for the Houston based tobacconist of the same name. I appreciate so much getting firsthand information from folks who where ‘there’ to understand better the story of the pipe on the worktable. This Zulu, Woodstock or Yachtsman has a good feel in the palm and reveals a dark finish with much briar grain to please the eye. The Zulu’s dimensions are Length: 5 7/8 inches, Height: 2 inches, Rim width: 1 5/16 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/2 inches. Jack commissioned this Pipe Pub and has the first opportunity to claim him in the Pipe Store. A portion of the proceeds of all the pipes restored go to help the Daughters of Bulgaria, (now called Spring of Hope) helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

This 1970s/early 80s survivor of the Pipe Pub ‘Personal Label’ production was most likely produced in London by Comoy’s. It was produced for the Houston based tobacconist of the same name. I appreciate so much getting firsthand information from folks who where ‘there’ to understand better the story of the pipe on the worktable. This Zulu, Woodstock or Yachtsman has a good feel in the palm and reveals a dark finish with much briar grain to please the eye. The Zulu’s dimensions are Length: 5 7/8 inches, Height: 2 inches, Rim width: 1 5/16 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/2 inches. Jack commissioned this Pipe Pub and has the first opportunity to claim him in the Pipe Store. A portion of the proceeds of all the pipes restored go to help the Daughters of Bulgaria, (now called Spring of Hope) helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Please pray for the people of Ukraine!

www.CratesforUkraine.com

www.Voice-Of-Ukraine.com

Pingback: A Cracked Shank Repair Brings a Comeaux USA 3-00 Canadian Back to Life – The Pipe Steward

Pingback: A Survivor of the Now Gone Bertram ‘The Nation’s Pipemaker’ – a Bertram Washington DC 30 Billiard – The Pipe Steward