Another interesting pipe has been commissioned coming from the Lot of 68. I saw this Lot of pipes on the eBay auction block in February 2019 from a seller in West Hartford, Connecticut. The time ran out and my bid was the last one standing. These pipes eventually made their way to the For “Pipe Dreamers” ONLY! online collection waiting for pipemen and women to commission. I have no idea which Billiard among so many Billiards in the photo is the Herter’s. Pipeman Aaron heard the whisper of this Billiard and reached out to me. This isn’t the first time Aaron commissioned a pipe, and this is what I wrote before about Aaron that he shared with me:

Pipeman Aaron heard the whisper of this Billiard and reached out to me. This isn’t the first time Aaron commissioned a pipe, and this is what I wrote before about Aaron that he shared with me:

What I discovered about Aaron is something I appreciate deeply. Not only do I appreciate that Aaron is a father of 3 children and 4 grandchildren, but I discovered that he is a Criminal Investigator in West Tennessee working for a city police department. In our communications, I discovered that he oversees all child abuse and sex crimes involving children. This vocation and focus connected him immediately with our support of the Daughters of Bulgaria. When my wife and I were in Bulgaria working with the Daughters, we were heart-sickened for the children we encountered on the streets of Bulgaria selling themselves. My appreciation for Aaron’s vocation and the difficulty of seeing the abuse of children runs deep. On the lighter side, I discovered that Aaron loves the outdoors, collects pipes and even has tried his hand at crafting a pipe. Lastly, Aaron describes himself as an old firearms hobbyist. I appreciate learning about the new stewards of the pipes I restore.

Since I wrote these words, the grandchild count might not be correct! The next pipe that whispered to Aaron is this very handsome straight Billiard.

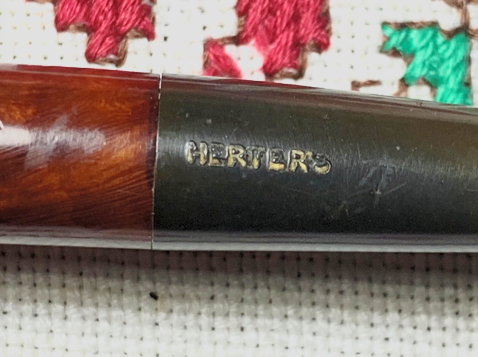

The nomenclature is stamped on the shank. On the left shank flank is stamped: HERTER’S [over] ANGLERS PIPE.

The nomenclature is stamped on the shank. On the left shank flank is stamped: HERTER’S [over] ANGLERS PIPE. The right side is stamped the COM and shape number: MADE IN [over] ENGLAND. To the right of this is stamped: 147.

The right side is stamped the COM and shape number: MADE IN [over] ENGLAND. To the right of this is stamped: 147. The left side of the stem has the logo: HERTER’S.

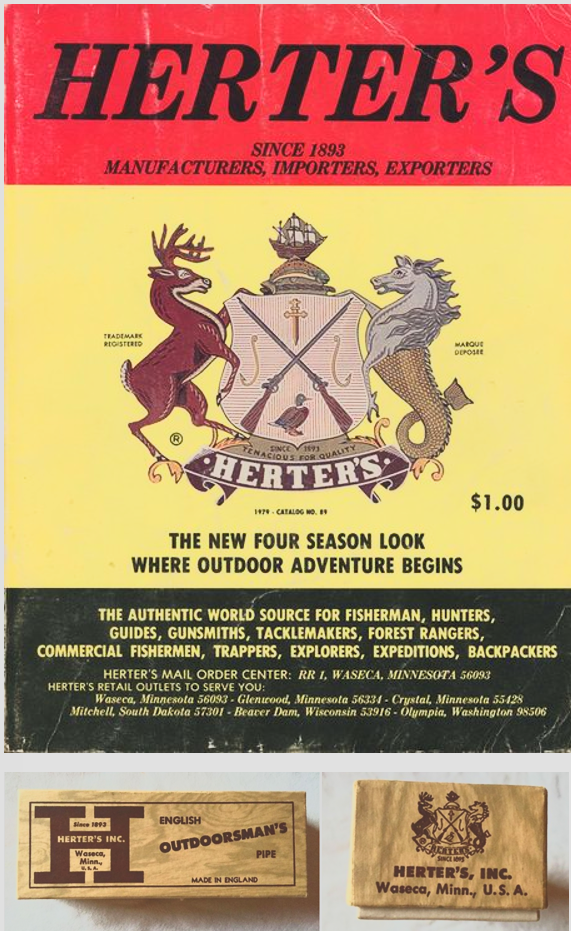

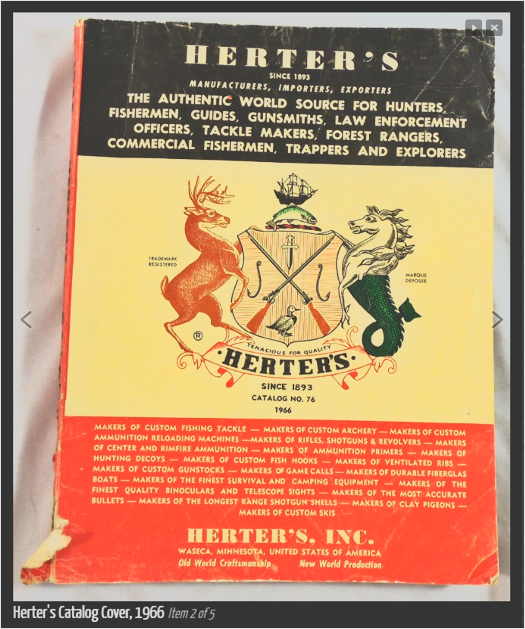

The left side of the stem has the logo: HERTER’S. It didn’t take long to find some interesting information about Herter’s. Pipedia’s post (Herter’s – Pipedia) provided some pictures with this question as the only text: “Apparently this outdoor outfitting company had pipes made for them?” Our COM is England, but the outdoor store described was in the US. There was a picture of a pipe along with a catalog cover, a box belonging to an ‘English Outdoorsman Pipe’, and what appears to be a match box with the information that Herter’s, INC. started in 1895 and was based in the US: Waseca, Minnesota. I love period ads. The catalog cover is great with the Herter’s registered trademark which has inscribed beneath the coat of arms this motto: “Tenacious for Quality”.

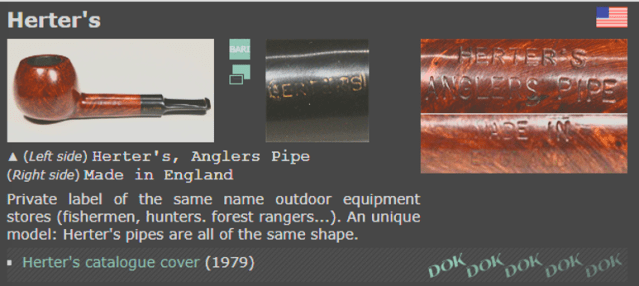

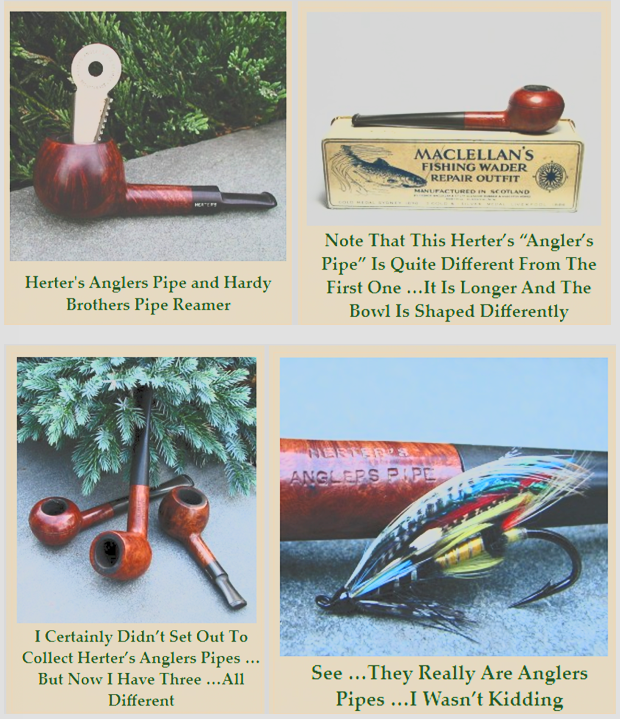

It didn’t take long to find some interesting information about Herter’s. Pipedia’s post (Herter’s – Pipedia) provided some pictures with this question as the only text: “Apparently this outdoor outfitting company had pipes made for them?” Our COM is England, but the outdoor store described was in the US. There was a picture of a pipe along with a catalog cover, a box belonging to an ‘English Outdoorsman Pipe’, and what appears to be a match box with the information that Herter’s, INC. started in 1895 and was based in the US: Waseca, Minnesota. I love period ads. The catalog cover is great with the Herter’s registered trademark which has inscribed beneath the coat of arms this motto: “Tenacious for Quality”. From Pipedia I swung over to Pipe Phil (He-Hh — Pipes : Logos & Markings) and found more information – some of which I questioned from the outset. The Apple shape shown in the panel below was also a Herter’s Anglers Pipe. Pipedia had the example of the “Outdoorsman” box and we have the “Angler”. Perhaps Herter’s had a pipe made for different hunting sports activities – that is cool! Or ‘Outdoorsman’ was a general name for the Angler Pipe in the box? The link provided for the catalog cover is referenced as being from 1979. The bit of information in the panel that I question is: “Herter’s pipes are all of the same shape.” We already know this is not correct as I look at the Herter’s Billiard on my worktable.

From Pipedia I swung over to Pipe Phil (He-Hh — Pipes : Logos & Markings) and found more information – some of which I questioned from the outset. The Apple shape shown in the panel below was also a Herter’s Anglers Pipe. Pipedia had the example of the “Outdoorsman” box and we have the “Angler”. Perhaps Herter’s had a pipe made for different hunting sports activities – that is cool! Or ‘Outdoorsman’ was a general name for the Angler Pipe in the box? The link provided for the catalog cover is referenced as being from 1979. The bit of information in the panel that I question is: “Herter’s pipes are all of the same shape.” We already know this is not correct as I look at the Herter’s Billiard on my worktable. The next question that came to mind was, ‘Is Herter’s still in operation?’ A simple Google search turned up a gold mine of information when I discovered this site: Herter’s Archives – Harvey County Historical Society. The information provided by the Harvey County Historical Museum Archives is repeated below in full because I want to archive it as well in the context of this Herter’s restoration. The article was posted August 8, 2014, by the museum’s curator, Kristine Schumucker:

The next question that came to mind was, ‘Is Herter’s still in operation?’ A simple Google search turned up a gold mine of information when I discovered this site: Herter’s Archives – Harvey County Historical Society. The information provided by the Harvey County Historical Museum Archives is repeated below in full because I want to archive it as well in the context of this Herter’s restoration. The article was posted August 8, 2014, by the museum’s curator, Kristine Schumucker:

Herter’s

“Actually, made far better than is necessary:” Herter’s Fishing Lure Molds Before Cabela’s, or even Wal-Mart, where did the serious fisherman (or woman) get supplies? From 1930 until the early 1970s, the answer was the mail order company located in Waseca, Minnesota – Herter’s.

Before Cabela’s, or even Wal-Mart, where did the serious fisherman (or woman) get supplies? From 1930 until the early 1970s, the answer was the mail order company located in Waseca, Minnesota – Herter’s. The owner, George Herter, produced catalogs that advertised a wide variety of gun, hunting, camping and fishing supplies. Herter was a master pitchman. He wrote all the copy for the catalog, some over 700 pages, claiming the superiority of Herter’s products over products sold by his competitors. His products, he bragged, were “actually made far better than is necessary.”

The owner, George Herter, produced catalogs that advertised a wide variety of gun, hunting, camping and fishing supplies. Herter was a master pitchman. He wrote all the copy for the catalog, some over 700 pages, claiming the superiority of Herter’s products over products sold by his competitors. His products, he bragged, were “actually made far better than is necessary.”

Recently a set of Herter fishing lure molds were donated to the museum with instructions on how to make.

Throughout the 1970s, Herter’s business declined as people shopped at K-Mart, Wal-Mart, and eventually, the ‘big box’ stores, like Cabala’s. The Herter’s Company went bankrupt in 1981, and George Herter died in 1994 at the age of 83. The Herter’s name is still used by Cabela’s on a line of pistol ammunition and some clothing.

The Herter’s name is still used by Cabela’s on a line of pistol ammunition and some clothing.

Doug Lodermeier, Minneapolis, MN, noted the importance of Herter’s, not only to Minnesota, but the whole industry.

“This Minnesota institution changed hunting and fishing in the state . . . It caused an explosion in the popularity of these activities . . . It put Minnesota on the map as a sportsmen’s paradise. And it dramatically changed the economics of retail. . . Herter’s was the beginning of a model that is still being perfected today and has caused the rapid decline in smaller, family-owned stores. . . Cabela’s wouldn’t exist without Herter’s.”

Do you have a favorite Herter’s product?

Sources:

- http://discovery.mnhs.org/MN150/index.php?title=Herter’s%2C_Inc.

- http://www.nytimes.com/2008/12/07/books/review/Collins-t.html?_r=0

- http://gunlore.awardspace.info/gunknow/herter.htm

- http://austinthompson.org/Thingmaker/FishingLures.shtm

From the Museum Archives I found that my good friend, Paresh Deshpande, had restored a Herter’s Anglers Pipe which was also a Billiard – 147. His post (Herter’s Angler Pipe | rebornpipes) uncovered even more information which I found helpful from Wikipedia about the eccentric founder of Herter’s outdoor goods and author which is a good read (George Leonard Herter – Wikipedia). Another interesting article Paresh found was from a 2015 The Minnesota Star Tribune (Herter’s catalog is long gone, but not forgotten). There is a good bit of information about George Leonard Herter, but not as much about one of his product lines – the Anglers Pipe. One last discovery made by Paresh to me was the best. He found a blog by Dean A. Smith of Ridgefield, Connecticut, that cut right to the heart of the matter (Tobacciana | Tackle Treasures):

Tobacciana

In the old days smoking and outdoor activities seemed to go hand-in-hand …thereby the vast proliferation of smoking products with angling themes. In fact, smoking was so popular that some tackle manufacturers offered smoking products and accessories. For example, both Hardy and Herters made “Anglers Pipes”. Now, I am not the least bit certain what distinguishes a normal pipe from an anglers pipe …but it did give me something else to collect and that’s all that matters. Hardy also made an “Anglers Pipe Reamer” …which begs the question, would it only work on “Anglers Pipes?” One final question about the Herter’s Anglers Pipe was pinging in my mind: Who made this pipe in England? I have a copy of Herb Wilczak and Tom Colwell’s (3/3/97) ‘Who Made That Pipe?’ I was rewarded with this information:

One final question about the Herter’s Anglers Pipe was pinging in my mind: Who made this pipe in England? I have a copy of Herb Wilczak and Tom Colwell’s (3/3/97) ‘Who Made That Pipe?’ I was rewarded with this information: Herter’s Anglers Pipes are specifically mentioned and produced by ‘John Higgins DBA Anglers Briar’. The name of John Higgin’s company was Anglers Briar. John Higgins is mentioned in Pipedia’s list of British Pipe Brands & Makers E – H – Pipedia, as having an old English brand called ‘English Patent Pipe’ which does not help. Broadening a search for John Higgins, I found a very helpful March 17, 2016 thread in Pipes Magazine Forums (Herters fisherman pipe :: Pipe Talk :: Pipe Smokers Forums of PipesMagazine.com) which starts from a pipeman seeking information about his pipe with the nomenclature the same as ours. One response brought up the Wilczak & Colwell’s reference to John Higgins which I did above. Another response got my attention from Pipes Magazine Lifer, Jon Guss. Here is what he posted (bold emphases are mine):

Herter’s Anglers Pipes are specifically mentioned and produced by ‘John Higgins DBA Anglers Briar’. The name of John Higgin’s company was Anglers Briar. John Higgins is mentioned in Pipedia’s list of British Pipe Brands & Makers E – H – Pipedia, as having an old English brand called ‘English Patent Pipe’ which does not help. Broadening a search for John Higgins, I found a very helpful March 17, 2016 thread in Pipes Magazine Forums (Herters fisherman pipe :: Pipe Talk :: Pipe Smokers Forums of PipesMagazine.com) which starts from a pipeman seeking information about his pipe with the nomenclature the same as ours. One response brought up the Wilczak & Colwell’s reference to John Higgins which I did above. Another response got my attention from Pipes Magazine Lifer, Jon Guss. Here is what he posted (bold emphases are mine):

Gentlemen,

Sorry for the delayed response.

Angler was indeed a brand belonging to John Higgins & Co. I’m not sure exactly when it was introduced but can tell you it appears in the 1921 Tobacco World Annual’s directory of Fancy Goods Brands and continues to be listed through the 1941 edition. For reasons I’ll explain later, I suspect it went out of production not that long afterward.

John Higgins, founder of the eponymous company, was born in Hammersmith, London in 1823. His parents were John and Ann, and at the time of his birth uninvolved in the pipe or tobacco industries (his father was a dealer in cheese). In the early spring of 1850 John married Charlotte Letitia Augustus. At that point his father’s profession is listed as a maker of silver spoons. An odd evolution from cheese, and I’d love to know the backstory. But the point I think is that the link between silversmiths and pipes is well known, and highly suggestive about John’s entry into the trade. In the wedding register he is listed as a turner, demonstrating that he was already a worker with wood. In fact, we know that by then John had been making and/or importing pipes for about two years: a company listing in 1906 claims 1848 as the year the business was established. Over the years references to the company’s activities vary, however, and it is not entirely clear the degree to which he manufactured entire pipes, or just stems, or was essentially an importer. We do know that John sold many ancillary products and was what was then called a “sundries man”; similarly, in most of the later censuses and business directories John and his company are generally listed as being an importer of fancy goods. During his lifetime the business had three successive locations, all in the greater London area; it started at 23 Wilderness Row, moved to 143 Aldersgate Street, and for about the last fifteen years before his death was at 10 Long Lane.

John Higgins, founder of the eponymous company, was born in Hammersmith, London in 1823. His parents were John and Ann, and at the time of his birth uninvolved in the pipe or tobacco industries (his father was a dealer in cheese). In the early spring of 1850 John married Charlotte Letitia Augustus. At that point his father’s profession is listed as a maker of silver spoons. An odd evolution from cheese, and I’d love to know the backstory. But the point I think is that the link between silversmiths and pipes is well known, and highly suggestive about John’s entry into the trade. In the wedding register he is listed as a turner, demonstrating that he was already a worker with wood. In fact, we know that by then John had been making and/or importing pipes for about two years: a company listing in 1906 claims 1848 as the year the business was established. Over the years references to the company’s activities vary, however, and it is not entirely clear the degree to which he manufactured entire pipes, or just stems, or was essentially an importer. We do know that John sold many ancillary products and was what was then called a “sundries man”; similarly, in most of the later censuses and business directories John and his company are generally listed as being an importer of fancy goods. During his lifetime the business had three successive locations, all in the greater London area; it started at 23 Wilderness Row, moved to 143 Aldersgate Street, and for about the last fifteen years before his death was at 10 Long Lane.

When John died in 1896 he left a sizable estate of 23,743 pounds (over $3 million in today’s money). His wife Charlotte having predeceased him, John left two sons and three daughters still living in 1896. From what I can tell none of the children (or their spouses) went into the family business. What’s clear is that about four months before he died John sold the company to Bob Reginald (“B. R.”) Arkell.

The son of a miller, Arkell was a cigar dealer/tobacconist born in Abingdon, Berkshire in 1842. He appears to have been interested in growing his business through acquisition (what today might be called a roll-up play), and after acquiring John Higgins & Co announced that he would “amalgamate with it the business of Mr. Eduoard Wolf”. Arkell’s name appears in various other contemporary records as a principal in other wholesale and retail tobacco businesses, including something called “The Tobacconists’ Supply Syndicate”. Arkell died in the fall of 1919, leaving his widow (second wife, Catherine Eleanor) a fortune of about 20,400 pounds. Bob and Catherine had two sons, Robert (1871-1949) and Thomas Reginald (1875-?). Robert went into the family business, while Thomas became a naval cadet. I haven’t dug much deeper than this, and so the history becomes murky at this point. Robert married and had three sons, and it is possible that they were involved in the family business with their father. But apparently not for too long. John Higgins disappears from the London phone books during WW2; it’s listed in 1941 but gone by 1943 (1942 is missing from the run I consulted). So, either the company changed its name, although there’s no sign of it that I could find, or it was an economic casualty of the war.

Arkell died in the fall of 1919, leaving his widow (second wife, Catherine Eleanor) a fortune of about 20,400 pounds. Bob and Catherine had two sons, Robert (1871-1949) and Thomas Reginald (1875-?). Robert went into the family business, while Thomas became a naval cadet. I haven’t dug much deeper than this, and so the history becomes murky at this point. Robert married and had three sons, and it is possible that they were involved in the family business with their father. But apparently not for too long. John Higgins disappears from the London phone books during WW2; it’s listed in 1941 but gone by 1943 (1942 is missing from the run I consulted). So, either the company changed its name, although there’s no sign of it that I could find, or it was an economic casualty of the war.

What is helpful about this post is that after John Higgins’ death in 1896, the company went through a few changes in ownership. It is apparent that the company produced Angler pipes for different distributions, Herter’s being one. The final observations about the John Higgins company was that it disappears from public records in the early 1940s. Jon Guss speculated that the company was perhaps a casualty of WW2, which was a fate not uncommon during that time. If this hypothesis is correct, and Anglers Briar no longer produced Angler pipes during WW2, then our pipe would have been produced and shipped to Minnesota with the Herter’s name stamped on it, no later than the early 1940s. During WW2, Europe’s supply of briar was greatly diminished, which impacted the entire pipe world at that time. Rubber stems were also at a premium with war shortages and repurposing supply chains. We are not 100% sure of this dating, because it’s possible that the company was later renamed and later continued production of pipes under the ‘Angler’ brand – but there’s no evidence of this.

I enjoy digging into the histories of pipes that come across my worktable. It gives me a better appreciation for the pipe which can be passed on to a new steward. Now, looking at the pipe itself, it is a classic Billiard workhorse of a pipe with a nice finish and grain. The chamber has a moderate cake build up. There is a thick lava flow crust over the rim which needs cleaning.

There is a thick lava flow crust over the rim which needs cleaning. The stummel has a few blemishes that I need to keep my eye on after the general cleaning.

The stummel has a few blemishes that I need to keep my eye on after the general cleaning. The stem has significant oxidation with the olive green hue showing.

The stem has significant oxidation with the olive green hue showing. The bit has some tooth chatter but looks good overall.

The bit has some tooth chatter but looks good overall. The tenon has a narrow tube stinger protruding. This fitment should keep moisture out of the airway. I haven’t seen one like this before.

The tenon has a narrow tube stinger protruding. This fitment should keep moisture out of the airway. I haven’t seen one like this before. The cleaning is commenced with cleaning the stinger tube with 0000 grade steel wool.

The cleaning is commenced with cleaning the stinger tube with 0000 grade steel wool. The airway is in good condition only taking a few pipe cleaners moistened with isopropyl 99% alcohol to clean.

The airway is in good condition only taking a few pipe cleaners moistened with isopropyl 99% alcohol to clean. To address the oxidation, a pipe cleaner is threaded through the airway to act as a handle for easier retrieval. The stem is then placed in a soak with Briarville’s Pipe Stem Oxidation Remover for several hours.

To address the oxidation, a pipe cleaner is threaded through the airway to act as a handle for easier retrieval. The stem is then placed in a soak with Briarville’s Pipe Stem Oxidation Remover for several hours. The chamber needs to be reamed to allow fresh briar to emerge and a new cake to be developed. To address the moderate carbon cake build up, the chamber is reamed with only the smallest blade from the Pipnet Reaming kit. This is followed by scraping the chamber wall with the Savinelli Fitsall Tool which does a good job getting at the sharper angles at the floor of the chamber.

The chamber needs to be reamed to allow fresh briar to emerge and a new cake to be developed. To address the moderate carbon cake build up, the chamber is reamed with only the smallest blade from the Pipnet Reaming kit. This is followed by scraping the chamber wall with the Savinelli Fitsall Tool which does a good job getting at the sharper angles at the floor of the chamber. To remove the last vestiges of carbon cake, the chamber is sanded with 220 grit paper wrapped around a dowel rod.

To remove the last vestiges of carbon cake, the chamber is sanded with 220 grit paper wrapped around a dowel rod. The pile of carbon removed is shown along with the tools used. After a quick inspection of the chamber, there is only healthy briar with no heating issues.

The pile of carbon removed is shown along with the tools used. After a quick inspection of the chamber, there is only healthy briar with no heating issues. Next the external briar is scrubbed with undiluted Murphy Oil Soap and a cotton pad. It’s surprising how much dirt collects on the surface.

Next the external briar is scrubbed with undiluted Murphy Oil Soap and a cotton pad. It’s surprising how much dirt collects on the surface. The rim had a layer of crusted lava flow over it and the brass brush goes to work on this. The brass is a ‘soft’ metal and is not overly invasive when scrubbing but adds some punch to the cleaning process. The Savinelli Fitsall Tool follows by carefully scraping the rim to remove the crust.

The rim had a layer of crusted lava flow over it and the brass brush goes to work on this. The brass is a ‘soft’ metal and is not overly invasive when scrubbing but adds some punch to the cleaning process. The Savinelli Fitsall Tool follows by carefully scraping the rim to remove the crust. The stummel is then taken to the sink to work on the internals using warm water, shank brushes, and anti-oil liquid dishwashing soap. The internals are scrubbed and then the stummel is thoroughly rinsed and returned to the worktable.

The stummel is then taken to the sink to work on the internals using warm water, shank brushes, and anti-oil liquid dishwashing soap. The internals are scrubbed and then the stummel is thoroughly rinsed and returned to the worktable. The internal cleaning continues with cotton buds and isopropyl 99% alcohol. The small dental spoon also scrapes the mortise wall to excavate accumulated gunk.

The internal cleaning continues with cotton buds and isopropyl 99% alcohol. The small dental spoon also scrapes the mortise wall to excavate accumulated gunk. During the cleaning of the internals, I discovered an interesting fact about the design of the Angler Pipe. I had noted earlier that I had not seen a stinger fitment like this one. It was a slender tube that was just large enough to allow the pipe cleaner to pass through. I understand now the reason for the stinger design. If you notice in the photo below, only cotton buds are used in the cleaning and no pipe cleaners. The reason for this is that the drilling of the airway is larger than the norm. With such an open airway, the air resistance puffing on this pipe would be too free and fast by itself. The tight tubular stinger provides the restriction necessary for a good puff. My general rule of thumb is that the pull on the pipe should be like pulling Coke up a straw. Not too much restriction, but enough for a balanced draw.

During the cleaning of the internals, I discovered an interesting fact about the design of the Angler Pipe. I had noted earlier that I had not seen a stinger fitment like this one. It was a slender tube that was just large enough to allow the pipe cleaner to pass through. I understand now the reason for the stinger design. If you notice in the photo below, only cotton buds are used in the cleaning and no pipe cleaners. The reason for this is that the drilling of the airway is larger than the norm. With such an open airway, the air resistance puffing on this pipe would be too free and fast by itself. The tight tubular stinger provides the restriction necessary for a good puff. My general rule of thumb is that the pull on the pipe should be like pulling Coke up a straw. Not too much restriction, but enough for a balanced draw. To make sure all is clean and the briar is refreshed, the stummel will receive a kosher salt and alcohol soak. The first step is to create a ‘wick’ with a cotton ball. The ball is pulled and twisted to form the wick.

To make sure all is clean and the briar is refreshed, the stummel will receive a kosher salt and alcohol soak. The first step is to create a ‘wick’ with a cotton ball. The ball is pulled and twisted to form the wick. The cotton wick is then guided through the mortise and out the draft hole with the help of the stiff hanger wire. The cotton helps to draw out the tars and oils from the internal briar.

The cotton wick is then guided through the mortise and out the draft hole with the help of the stiff hanger wire. The cotton helps to draw out the tars and oils from the internal briar. Next, after the bowl is filled with kosher salt and placed in the egg carton with the rim and shank facing level, isopropyl 99% alcohol is placed in the bowl until it surfaces over the salt. Kosher salt is used because it doesn’t leave an aftertaste like regular iodized table salt.

Next, after the bowl is filled with kosher salt and placed in the egg carton with the rim and shank facing level, isopropyl 99% alcohol is placed in the bowl until it surfaces over the salt. Kosher salt is used because it doesn’t leave an aftertaste like regular iodized table salt. After about 10 minutes the alcohol has been absorbed into the salt and cotton and again is topped off. The stummel will soak for several hours through the night.

After about 10 minutes the alcohol has been absorbed into the salt and cotton and again is topped off. The stummel will soak for several hours through the night. The next day, the cotton wick shows some soiling indicating the soak working through the night.

The next day, the cotton wick shows some soiling indicating the soak working through the night. To make sure the internals are clean, a couple of cotton buds are used to confirm this. A whiff test also is good. There are no lingering ghosts in the closet.

To make sure the internals are clean, a couple of cotton buds are used to confirm this. A whiff test also is good. There are no lingering ghosts in the closet. The stem has been soaking in Briarville’s Pipe Stem Oxidation Remover. When the stem is fished out, it is rubbed aggressively with a cloth to remove any raised oxidation. The airway is also cleaned with a pipe cleaner and isopropyl 99% alcohol to clear away any of the Briarville fluid. The soak did a good job.

The stem has been soaking in Briarville’s Pipe Stem Oxidation Remover. When the stem is fished out, it is rubbed aggressively with a cloth to remove any raised oxidation. The airway is also cleaned with a pipe cleaner and isopropyl 99% alcohol to clear away any of the Briarville fluid. The soak did a good job. The stem is in very nice shape. The only bite compression I see is on the upper bit. The compression is very light. To erase the light compression the heating method is used. The flame of a Bic lighter paints the bit. As the vulcanite heats the rubber expands and regains its original condition – or closer to it. The before and after picture shows that the compression was totally removed.

The stem is in very nice shape. The only bite compression I see is on the upper bit. The compression is very light. To erase the light compression the heating method is used. The flame of a Bic lighter paints the bit. As the vulcanite heats the rubber expands and regains its original condition – or closer to it. The before and after picture shows that the compression was totally removed. From the picture above, you can see that the vulcanite surface is rough. To smooth the vulcanite and to remove any imperfections on the upper bit, 320 grit paper sands the upper bit.

From the picture above, you can see that the vulcanite surface is rough. To smooth the vulcanite and to remove any imperfections on the upper bit, 320 grit paper sands the upper bit. The sanding expands to the entire stem with the 320 grit paper. To guard the stem facing from shouldering, the stem is remounted on the stummel with the plastic guard pinched between. The sanding butts up to the guard without going over the stem’s edge. Care is also given to sand around the Herter’s stem logo.

The sanding expands to the entire stem with the 320 grit paper. To guard the stem facing from shouldering, the stem is remounted on the stummel with the plastic guard pinched between. The sanding butts up to the guard without going over the stem’s edge. Care is also given to sand around the Herter’s stem logo. After finishing with the 320 grit paper I heard my wife calling to remind me of our plan to go to the annual Golden Candlelight Walk. This is a Golden, Colorado tradition which is fun for the family. Of course, getting dressed warm is required. We met up with several folks from our church in Golden and walked with our candles down Golden’s main street, Washington Avenue, listening to folks singing Christmas carols as we strolled. Yes, I wore Miami Dolphins paraphernalia in Denver Broncos land 😊.

After finishing with the 320 grit paper I heard my wife calling to remind me of our plan to go to the annual Golden Candlelight Walk. This is a Golden, Colorado tradition which is fun for the family. Of course, getting dressed warm is required. We met up with several folks from our church in Golden and walked with our candles down Golden’s main street, Washington Avenue, listening to folks singing Christmas carols as we strolled. Yes, I wore Miami Dolphins paraphernalia in Denver Broncos land 😊. Back to the worktable after a great time, and back to sanding the stem. Following the 320 paper, the stem is taken to the sink where it is wet sanded with 600 grit paper. This is followed with applying 0000 grade steel wool.

Back to the worktable after a great time, and back to sanding the stem. Following the 320 paper, the stem is taken to the sink where it is wet sanded with 600 grit paper. This is followed with applying 0000 grade steel wool. The primary sanding transitions to more of a polishing using micromesh pads. Between each of the 9 pads, Obsidian Oil is lightly applied to the stem to condition it and to guard against oxidation developing. First, pads 1500, 1800, and 2400 are applied.

The primary sanding transitions to more of a polishing using micromesh pads. Between each of the 9 pads, Obsidian Oil is lightly applied to the stem to condition it and to guard against oxidation developing. First, pads 1500, 1800, and 2400 are applied. Next, pads 3200, 3600 and 4000 are applied.

Next, pads 3200, 3600 and 4000 are applied. Finally, pads 6000, 8000 and 12000 are applied to the stem. With these final 3 pads, the Herter’s logo is lightly sanded.

Finally, pads 6000, 8000 and 12000 are applied to the stem. With these final 3 pads, the Herter’s logo is lightly sanded. With the stem on the sideline, it’s time to take a closer look at the stummel after the general cleaning. There is no doubt that this rim has seen better days. If one sees ‘through’ the char stains you can see very nice looking grain that is begging to reemerge. The front of the bowl has more charring on the inside and outside edges of the rim.

With the stem on the sideline, it’s time to take a closer look at the stummel after the general cleaning. There is no doubt that this rim has seen better days. If one sees ‘through’ the char stains you can see very nice looking grain that is begging to reemerge. The front of the bowl has more charring on the inside and outside edges of the rim. Looking at the front, the charring is evident. My guess is the former steward pulled the flame over the front at this place when lighting his tobacco.

Looking at the front, the charring is evident. My guess is the former steward pulled the flame over the front at this place when lighting his tobacco. There are two old fills that need attention. The larger on the front of the bowl, and the lesser on the right back side of the shank.

There are two old fills that need attention. The larger on the front of the bowl, and the lesser on the right back side of the shank. The first step is to dig out the old fill material using a sharp dental probe.

The first step is to dig out the old fill material using a sharp dental probe. To repatch the pits, briar putty is used. After laying down strips of scotch tape on the plastic work palette for easier clean up later, a small pile of briar dust is placed near a dollop of regular clear CA glue. The patch areas are cleaned with alcohol. The toothpick is used to draw the briar dust into the glue and mixed. More dust is pulled into the mixture until the viscosity of the mixture is like molasses – thick enough so that it stays put when placed on the pit, but not so thick that the mixture solidifies too rapidly.

To repatch the pits, briar putty is used. After laying down strips of scotch tape on the plastic work palette for easier clean up later, a small pile of briar dust is placed near a dollop of regular clear CA glue. The patch areas are cleaned with alcohol. The toothpick is used to draw the briar dust into the glue and mixed. More dust is pulled into the mixture until the viscosity of the mixture is like molasses – thick enough so that it stays put when placed on the pit, but not so thick that the mixture solidifies too rapidly. When the mixture seems about right, the toothpick trowels the Briar Putty to the pits. You can see the thickness of the mixture from what is left over on the tip of the toothpick. The stummel is then put aside allowing the patches to fully cure. With that, it’s time to turn off the lights. It’s been a good day.

When the mixture seems about right, the toothpick trowels the Briar Putty to the pits. You can see the thickness of the mixture from what is left over on the tip of the toothpick. The stummel is then put aside allowing the patches to fully cure. With that, it’s time to turn off the lights. It’s been a good day. The next morning, the patches have cured and needle files go to work on the patch mounds bringing them down flush with the briar surface.

The next morning, the patches have cured and needle files go to work on the patch mounds bringing them down flush with the briar surface. After the filing, 220 grit paper smooths the patch further. The challenge in doing patches on a stummel with a darker finish is the bald spot the sanding creates. Blending these patches so that they don’t stand out is the goal. I’ll complete the sanding process for the stummel before addressing the finish.

After the filing, 220 grit paper smooths the patch further. The challenge in doing patches on a stummel with a darker finish is the bald spot the sanding creates. Blending these patches so that they don’t stand out is the goal. I’ll complete the sanding process for the stummel before addressing the finish. After the 220 paper, 320 then 600 are used on the patches.

After the 220 paper, 320 then 600 are used on the patches. Next, we need to work on the rim. It’s in rough shape with char stains on the rim surface and a char ring round the inner rim edge. The outer rim edge is also charred towards the front of the bowl.

Next, we need to work on the rim. It’s in rough shape with char stains on the rim surface and a char ring round the inner rim edge. The outer rim edge is also charred towards the front of the bowl. To address this the stummel is topped using a piece of 220 paper on the chopping board.

To address this the stummel is topped using a piece of 220 paper on the chopping board. After rotating the stummel over the paper several times a quick look shows the progress. The rim is cleaning but dark spots and the char rings can still be seen.

After rotating the stummel over the paper several times a quick look shows the progress. The rim is cleaning but dark spots and the char rings can still be seen. After more rotating and inspecting, enough sanding has been done with 220 grit paper.

After more rotating and inspecting, enough sanding has been done with 220 grit paper. The 220 grit paper is followed by 320 grit paper and then 600. Grain can be seen trying to make an appearance after the 600 grit paper topping.

The 220 grit paper is followed by 320 grit paper and then 600. Grain can be seen trying to make an appearance after the 600 grit paper topping. At this point, much of the rim edge charring has been removed by the topping, but the inner rim edge still shows a ring and the roundness of the chamber mouth needs refreshing.

At this point, much of the rim edge charring has been removed by the topping, but the inner rim edge still shows a ring and the roundness of the chamber mouth needs refreshing. To do this a smart bevel is created using sanding paper pinched between the inner rim edge and the wooden orb. I call the bevel ‘smart’ because with the hard surface backing the paper, it creates a much crisper edge. Using just the thumb pressed against the paper and edge will result in a rounder bevel which is good in some cases.

To do this a smart bevel is created using sanding paper pinched between the inner rim edge and the wooden orb. I call the bevel ‘smart’ because with the hard surface backing the paper, it creates a much crisper edge. Using just the thumb pressed against the paper and edge will result in a rounder bevel which is good in some cases. The bevel is created with 220, 320 and 600 grade papers in succession. Each strip is pinched around the wooden orb and then rotated around the chamber mouth.

The bevel is created with 220, 320 and 600 grade papers in succession. Each strip is pinched around the wooden orb and then rotated around the chamber mouth. The result is stellar. The before and after comparison tells the story.

The result is stellar. The before and after comparison tells the story. Next, the full set of 9 micromesh pads is used to sand/polish the stummel. Between each pad the stummel is wiped with a moist cloth to remove the accumulated dust and to improve the traction of the next pad. The first set of 3 pads are grades 1500, 1800 and 2400.

Next, the full set of 9 micromesh pads is used to sand/polish the stummel. Between each pad the stummel is wiped with a moist cloth to remove the accumulated dust and to improve the traction of the next pad. The first set of 3 pads are grades 1500, 1800 and 2400. The next set are grades 3200, 3600 and 4000.

The next set are grades 3200, 3600 and 4000. The final set of pads are grades 6000, 8000, 12000. The natural darkness of the briar is teased out through the micromesh sanding. The grain looks great. The patches on the front of the bowl and the shank have blended more, but they will continue to be visible. They will serve as this Herter’s badge of honor of his vintage past as he gets ready to serve a new steward.

The final set of pads are grades 6000, 8000, 12000. The natural darkness of the briar is teased out through the micromesh sanding. The grain looks great. The patches on the front of the bowl and the shank have blended more, but they will continue to be visible. They will serve as this Herter’s badge of honor of his vintage past as he gets ready to serve a new steward. Mark Hoover’s ‘Before & After’ Restoration Balm (www.Lbepen.com) does a great job bringing out the natural hues of the briar and conditions it as well. After putting some Balm on the finger, the Balm is worked into the briar and then set aside for about 10 or so minutes for the Balm to do what it does.

Mark Hoover’s ‘Before & After’ Restoration Balm (www.Lbepen.com) does a great job bringing out the natural hues of the briar and conditions it as well. After putting some Balm on the finger, the Balm is worked into the briar and then set aside for about 10 or so minutes for the Balm to do what it does. After the time has passed, a dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the shine. I’m liking what I’m seeing!

After the time has passed, a dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the shine. I’m liking what I’m seeing! One mini project before moving on to applying compound. The Herter’s stem logo has some residual paint, but it needs to be refreshed.

One mini project before moving on to applying compound. The Herter’s stem logo has some residual paint, but it needs to be refreshed. I was just at Hobby Lobby yesterday with my wife getting some Christmas odds and ends, and I remembered that I had written on my ‘to do’ list to buy a new bottle of white acrylic paint. The new bottle was shaken pretty well, and some paint was applied over the Herter’s logo. I didn’t take a photo of the paint because what came out was more and thicker than what I expected. A cotton pad was then used to blot the wet paint to thin it and to quicken the drying.

I was just at Hobby Lobby yesterday with my wife getting some Christmas odds and ends, and I remembered that I had written on my ‘to do’ list to buy a new bottle of white acrylic paint. The new bottle was shaken pretty well, and some paint was applied over the Herter’s logo. I didn’t take a photo of the paint because what came out was more and thicker than what I expected. A cotton pad was then used to blot the wet paint to thin it and to quicken the drying. After drying, the side of a toothpick is used to scrape the excess paint off the logo. The form of the logo is nice and deep. The paint adheres to the logo nicely.

After drying, the side of a toothpick is used to scrape the excess paint off the logo. The form of the logo is nice and deep. The paint adheres to the logo nicely. The logo looks great.

The logo looks great. After sanding and then applying the micromesh pads, the briar darkened a good bit which helped to blend the lighter bald spots where there were patches and the rim which was topped. As I look at the rim compared to the briar below it, the rim appears to my eye to be a micro shade lighter, and it lost a bit of redness. I’m a bit nervous about applying a dye stick which might not match the stummel hues.

After sanding and then applying the micromesh pads, the briar darkened a good bit which helped to blend the lighter bald spots where there were patches and the rim which was topped. As I look at the rim compared to the briar below it, the rim appears to my eye to be a micro shade lighter, and it lost a bit of redness. I’m a bit nervous about applying a dye stick which might not match the stummel hues. I looked at my rough palette of colors which is on the surface of the chopping board. The list on the right are the dye sticks I have available. I settled on the Maple dye stick and made a very small test application on the rim. It looked good.

I looked at my rough palette of colors which is on the surface of the chopping board. The list on the right are the dye sticks I have available. I settled on the Maple dye stick and made a very small test application on the rim. It looked good. The maple dye stick applied dye to the entire rim, and it also touched up the areas around the patches on the stummel. I think it looks good. The hue was leveraged toward the finish and the blend looks good.

The maple dye stick applied dye to the entire rim, and it also touched up the areas around the patches on the stummel. I think it looks good. The hue was leveraged toward the finish and the blend looks good. Now on the homestretch. After mounting a dedicated cotton cloth buffing wheel onto the rotary tool, with the speed set at about 40% full power, Blue Diamond compound is applied to the stem and stummel.

Now on the homestretch. After mounting a dedicated cotton cloth buffing wheel onto the rotary tool, with the speed set at about 40% full power, Blue Diamond compound is applied to the stem and stummel. Applying the compound creates a lot of compound dust adhering to the surface. A felt cloth is used to clear away the dust and to prepare the surface to receive the wax.

Applying the compound creates a lot of compound dust adhering to the surface. A felt cloth is used to clear away the dust and to prepare the surface to receive the wax. With another cotton cloth wheel mounted at the same speed, carnauba wax is applied to the pipe. After the application, a microfiber cloth is used to give the pipe a vigorous hand buffing to remove excess wax and to raise the shine.

With another cotton cloth wheel mounted at the same speed, carnauba wax is applied to the pipe. After the application, a microfiber cloth is used to give the pipe a vigorous hand buffing to remove excess wax and to raise the shine. I’m pleased with how this probable late 1930s to early 1940s HeRter’s Angler Pipe came out. The story of the Herter name and business and the Angler Pipe producer, John Higgins in London, England is both interesting and helpful to appreciate the pipe. The grain is stellar and the Billiard shape is classic. Police detective Aaron commissioned the Herter’s and will have the first opportunity to claim him from the Pipe Steward Store. A large portion of the proceeds of all pipes restored help to support the work of the Daughters of Bulgaria, now called Spring of Hope. Thanks for joining me!

I’m pleased with how this probable late 1930s to early 1940s HeRter’s Angler Pipe came out. The story of the Herter name and business and the Angler Pipe producer, John Higgins in London, England is both interesting and helpful to appreciate the pipe. The grain is stellar and the Billiard shape is classic. Police detective Aaron commissioned the Herter’s and will have the first opportunity to claim him from the Pipe Steward Store. A large portion of the proceeds of all pipes restored help to support the work of the Daughters of Bulgaria, now called Spring of Hope. Thanks for joining me!

Another amazing job!…. Spent so many hours digging through those catalogs when I was a kid… Still have a few pieces of hunting clothing from there.

LikeLike

That’s really interesting, Aaron. The catalogs were definitely interesting pieces. I hope you enjoy your new Herter’s!

LikeLike