This will be my last pipe restoration of 2025 and officially declared to be a ‘Pipe for Christmas’ because of the festive vibe it invites. The ruby red finish, the gold band and the black acrylic stem – all shout, ‘Merry Christmas!’ with promises of a bowlful of Christmas blend. My wife and I will be packing up our small R-pod travel trailer and heading to Orange County California to celebrate Christmas with our daughter and her family – including 2 of our 11 grandchildren. The Yves of St. Claude, France came to me as a donation from a generous pipeman in the Kansas City area. In January 2019 I was still living in Sofia, Bulgaria when I received a letter with the offer of a Lot of 16 pipes. Here are the first words of that letter:

Greetings, Dal, from the middle of the USA where it is cold, foggy, and wintery. By way of introduction, I am —– —————. We have communicated a handful of times via one of the pipe groups on Facebook. Your posts have allowed me to read about your restoration work in support of the Daughters of Bulgaria. I find your pipe restoration work fascinating and your true mission inspiring.

I am so, so thankful for the generosity of pipemen like this that I have had the privilege of meeting via The Pipe Steward. After working through all the customs regulations, the Lot of pipes reached me in Bulgaria, and I took this picture. The Pipe for Christmas is on the bottom of several very nice pipes all helping to support the work of the Daughters of Bulgaria, now called Spring of Hope. My wife and I co-founded this work in Bulgaria which seeks to help women and girls who have been trafficked and sexually exploited. The Pipe for Christmas whispered to a particular pipeman. Pipeman Steve is an attorney in the Big Apple, Sinatra’s town and ground zero for the New Years celebration countdown – New York City. In my communications with Steve I found that he loves his job that he says is never boring which includes competition and the mental challenge required in heading off problems for his clients. I especially appreciated these words:

The Pipe for Christmas whispered to a particular pipeman. Pipeman Steve is an attorney in the Big Apple, Sinatra’s town and ground zero for the New Years celebration countdown – New York City. In my communications with Steve I found that he loves his job that he says is never boring which includes competition and the mental challenge required in heading off problems for his clients. I especially appreciated these words:

As to pipes, I am 52 and relatively new to the art, smoking intermittently on and off over the last 10 years. I thoroughly enjoy not only the contemplative act of smoking itself, but the craftsmanship and history of the pipes. I don’t have a huge collection—less than 10 pipes—nearly all of the newly purchased online (I did purchase one Savinelli in a pipe shop in Bloomington Indiana). These purchases from you will be my first foray into estate pipes, and I love the write up and process you provide. You are a gifted writer, and half my enjoyment of reading each of your blogs is both your historical research and occasional references to tangential culture or literary issues. Great stuff, Dal.

Steve’s first foray into estate pipes adds the pressure! The two pipes Steve commissioned are both interesting pipes. The first is a second of Dunhill, an attractive Parker Super Bruyere 189 Made in London England ④. The second is the ‘Christmas Pipe’ – the Yves of St. Claude. Here are pictures I received from the generous pipeman of Steve’s second commission.

The second is the ‘Christmas Pipe’ – the Yves of St. Claude. Here are pictures I received from the generous pipeman of Steve’s second commission.

The nomenclature is crisp and clear. Stamped on the left side of the shank in fancy cursive is Yves St. Claude [over] ELYSEE.

The nomenclature is crisp and clear. Stamped on the left side of the shank in fancy cursive is Yves St. Claude [over] ELYSEE. The right shank side is stamped the COM in a circle with ‘IN’ in the center: MADE IN FRANCE. To the right of the COM is the shape number, 55 which is pointing to the classic straight Billiard shape.

The right shank side is stamped the COM in a circle with ‘IN’ in the center: MADE IN FRANCE. To the right of the COM is the shape number, 55 which is pointing to the classic straight Billiard shape. The stem logo are the fancy initials, YStC of Yves St. Claude.

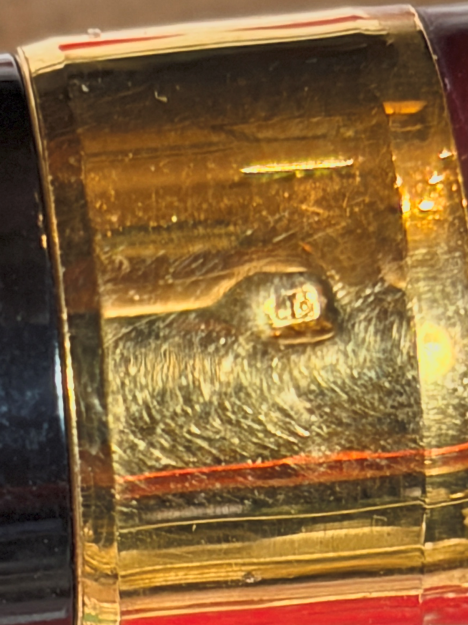

The stem logo are the fancy initials, YStC of Yves St. Claude. The band has a mark which is not a gold assay mark indicating pure gold, but a tiny stamp which would have a number in it indicating that this band is a percentage of gold – gold plated. After looking at it in a magnifying glass, my best guess is that the number is 18 but can’t be sure.

The band has a mark which is not a gold assay mark indicating pure gold, but a tiny stamp which would have a number in it indicating that this band is a percentage of gold – gold plated. After looking at it in a magnifying glass, my best guess is that the number is 18 but can’t be sure. If I do see an 18, this is what Crown Jewelers & Pawn says (A Guide To Understanding Gold Stamps, Purity And Value – Pawn Shop in Salt Lake City) along with other possible numbers:

If I do see an 18, this is what Crown Jewelers & Pawn says (A Guide To Understanding Gold Stamps, Purity And Value – Pawn Shop in Salt Lake City) along with other possible numbers: To find out more about the Yves name, my first stop is Pipedia (Yves Grenard – Pipedia) where I find a reference from Jose’ Manuel Lopes’ stellar book, ‘Pipes – Artisans and Trademarks’ which I have the privilege of owning:

To find out more about the Yves name, my first stop is Pipedia (Yves Grenard – Pipedia) where I find a reference from Jose’ Manuel Lopes’ stellar book, ‘Pipes – Artisans and Trademarks’ which I have the privilege of owning:

Yves Grenard is the brand and name of the director of the French factory Chapuis-Comoy, which produces Chacom. Second cousin of Pierre Comoy (see Comoy’s), he has run the company since 1971 and presides over the Chambre syndicale des fabricants de la région de Saint-Claude and the Confrérie des maîtres-pipiers de Saint-Claude.

With the connection traced to the Chapuis-Comoy name, the next stop is another reference from Lopes’ ‘Pipes – Artisans and Trademarks’ (Chapuis-Comoy – Pipedia):

Chapuis-Comoy is a factory in Saint-Claude, France.

It began with Francois Comoy who, in 1825, was making pipes in boxwood and other types, as well as clay pipes, for the armies of Napoleon. In 1856, the Comoy factory was the first to produce briar bowls at Saint-Claude. In 1870, Francois’s grandson, Henri Comoy (1850-1924) was taken prisoner in Switzerland whilst serving in the French army during the Franco-Prussian war, where he found his cousins, the Chapuis. This meeting produced the idea of an association, which only became a reality in 1922, with the creation of Chapuis-Comoy. After Henri’s death, his sons Paul and Adrien, took over the company with the support of their cousins, Emile and Louis Chapuis Sr., and in 1928 they created the Chacom brand.

In 1932, due to the economic crisis at Saint-Claude, the factory merged with La Bruyère, adopting that name, and becoming one of the biggest pipe companies in the world, with 450 workers. Louis Chapuis Jr., joined the company in 1938 and Pierre Comoy in 1947. The name Chapuis-Comoy returned in 1957 (125 workers), due to the success of the Chacom brand in France. In 1971, the London factory (see Comoy’s) became independent, and Yves Grenard, second cousin to Pierre, took over Saint-Claude, and is still running it. Between 1987 and 2001, the factory, which employed over 40 people, joined the Cuty-Fort Enterprises SA holding and, in 1994, included the Ropp brand in its catalog.

When ever I dive into the histories of French pipe makers it always is a spaghetti web of relationships. Yves Grenard emerges in the last paragraph of the Chapuis-Comoy history when, as a Comoy cousin, he took over the St. Claude arm of production. The panel from PipePhil dedicated to Yves Saint-Claude references Chapuis as the source of the Yves pipes (Y — Pipes: Logos & Markings). Following the Pipephil Chapuis-Comoy link (http://pipephil.eu/logos/en/logo-c4.html#chap) I found no reference to Yves Grenard, but followed a link there with information about the Chapuis-Comoy factory in St. Claude that did reference Yves Grenard (http://pipephil.eu/logos/en/infos/chapuiscomoy-en.html). The timeline on this page led to 1972 and following:

Following the Pipephil Chapuis-Comoy link (http://pipephil.eu/logos/en/logo-c4.html#chap) I found no reference to Yves Grenard, but followed a link there with information about the Chapuis-Comoy factory in St. Claude that did reference Yves Grenard (http://pipephil.eu/logos/en/infos/chapuiscomoy-en.html). The timeline on this page led to 1972 and following:

1972

1972

The society recovers its whole independence to London thanks to Yves Grenard, grand cousin of Pierre Comoy (Henry’s grandson) and manager of Chapuis-Comoy & Cie.

1988

Creation of the S.A. Cuty-Fort(2) bringing together Chapuis-Comoy, Emile Vuillard, Jeantet-David and Jean Lacroix. They have the production in common, but the different brands are preserved for the pipe’s distribution.

Creation of the S.A. Cuty-Fort(2) bringing together Chapuis-Comoy, Emile Vuillard, Jeantet-David and Jean Lacroix. They have the production in common, but the different brands are preserved for the pipe’s distribution.

2012

Yves Grenard passed away on Feb 8, 2012. His son Antoine manages Chapuis-Comoy & Cie.

One more snippet of information confirming that Yves St. Claude is a product of Chapuis-Comoy. The Pipephil Chapuis-Comoy panel (http://pipephil.eu/logos/en/infos/chapuiscomoy-en.html) has one example of a C-C pipe and includes the COM stamp which is identical to our Yves: The last bit of information has to do with the ELYSEE stamped beneath the Yves St. Claude on the shank. The Elysee Palace in Paris is what I believe is being referenced. The Elysee Palace for the French would be like the Buckingham Palace for the Brits or the White House for Americans. The photo shows the palace that is a symbol of French history, power and culture (https://pixabay.com/photos/london-palace-architecture-tourism-8835826/).

The last bit of information has to do with the ELYSEE stamped beneath the Yves St. Claude on the shank. The Elysee Palace in Paris is what I believe is being referenced. The Elysee Palace for the French would be like the Buckingham Palace for the Brits or the White House for Americans. The photo shows the palace that is a symbol of French history, power and culture (https://pixabay.com/photos/london-palace-architecture-tourism-8835826/). Here’s what Wikipedia has to say about the Elysee Palace (Élysée Palace – Wikipedia):

Here’s what Wikipedia has to say about the Elysee Palace (Élysée Palace – Wikipedia):

The Élysée Palace (French: Palais de l’Élysée, pronounced [palɛ d(ə) lelize]) is the official residence of the president of France in Paris. Completed in 1722, it was built for Louis Henri de La Tour d’Auvergne, a nobleman and army officer who had been appointed governor of Île-de-France in 1719. It is located on the Rue du Faubourg Saint-Honoré in the 8th arrondissement, near the Champs-Élysées. The name Élysée derives from the Elysian Fields, the place of the blessed dead in Greek mythology.

The Élysée Palace has been the home of personalities such as Madame de Pompadour (1721–1764), Nicolas Beaujon (1718–1786), Bathilde d’Orléans (1750–1822), Joachim Murat (1767–1815), and Charles Ferdinand, Duke of Berry (1778–1820). On 12 December 1848, under the Second Republic, the French Parliament passed a law declaring the building the official residence of the French president. The Élysée Palace, which contains the presidential office and residency, is also the meeting place of the Council of Ministers, the weekly meeting of the Government of France that is presided over by the president of the Republic. Across the street is the Hôtel de Marigny, which has served as a state guest house where the French government has hosted visiting dignitaries.

This is about as much as I can bring to light about the Yves Christmas Pipe on the worktable. With a better understanding and appreciation of this pipe’s story, it’s time to look at the pipe itself. The pipe overall is in very good shape. For the most part, general cleaning and a bling sprucing is all this pipe needs. The chamber has light carbon cake build up. This will be cleared allowing the new steward to develop a fresh cake that should be about the width of a US dime. The picture above and below show the slight darkening of the rim from lighting the blend in the bowl.

The picture above and below show the slight darkening of the rim from lighting the blend in the bowl. The ‘18K’ (if I made it out correctly!) gold band has some fine scratches from normal wear. I’ll spruce up the band a bit by polishing it.

The ‘18K’ (if I made it out correctly!) gold band has some fine scratches from normal wear. I’ll spruce up the band a bit by polishing it. The gold YSC stem logo needs some refreshing as well.

The gold YSC stem logo needs some refreshing as well. The black acrylic bit has minor tooth chatter and normal signs of wear.

The black acrylic bit has minor tooth chatter and normal signs of wear. The ‘spruce up’ of the YSC starts with cleaning the airway. One pipe cleaner moistened with isopropyl 99% alcohol is all that is needed.

The ‘spruce up’ of the YSC starts with cleaning the airway. One pipe cleaner moistened with isopropyl 99% alcohol is all that is needed. To address the tooth chatter on the bit, first 220 grit paper is used.

To address the tooth chatter on the bit, first 220 grit paper is used. Following 220 grit paper, 320 grit paper is used on the bit.

Following 220 grit paper, 320 grit paper is used on the bit. Next, the bit area is sanded with 600 grit paper and then 0000 grade steel wool is applied.

Next, the bit area is sanded with 600 grit paper and then 0000 grade steel wool is applied. Moving next to applying the full set of micromesh pads, Obsidian Oil is applied to the stem between each pad to condition the stem. First, pads 1500, 1800 and 2400 are applied to the entire stem. For the first 6 pads, the YSC logo is avoided.

Moving next to applying the full set of micromesh pads, Obsidian Oil is applied to the stem between each pad to condition the stem. First, pads 1500, 1800 and 2400 are applied to the entire stem. For the first 6 pads, the YSC logo is avoided. Next, grades 3200, 3600 and 4000 grade pads are applied to the stem.

Next, grades 3200, 3600 and 4000 grade pads are applied to the stem. Finally, pads 6000, 8000 and 12000 grade pads are applied. For this set of 3, the stem logo is also included.

Finally, pads 6000, 8000 and 12000 grade pads are applied. For this set of 3, the stem logo is also included. After applying the pads to the stem logo, the letters were cleaned up nicely and really do not need additional paint to refresh them. I’ll reconsider this later after working on the stummel.

After applying the pads to the stem logo, the letters were cleaned up nicely and really do not need additional paint to refresh them. I’ll reconsider this later after working on the stummel. Turning now to the stummel, the chamber is reamed to remove the very light carbon cake.

Turning now to the stummel, the chamber is reamed to remove the very light carbon cake. The Pipnet Reaming Kit is used. The chamber is large and it took 3 of the 4 blades available to ream the chamber.

The Pipnet Reaming Kit is used. The chamber is large and it took 3 of the 4 blades available to ream the chamber. The reaming was followed by scraping the chamber wall with the Savinelli Fitsall Tool which does a good job reaching the sharp angles in the floor of the chamber.

The reaming was followed by scraping the chamber wall with the Savinelli Fitsall Tool which does a good job reaching the sharp angles in the floor of the chamber. The last vestiges of carbon cake are removed by sanding the chamber with 220 grit paper wrapped around a dowel rod.

The last vestiges of carbon cake are removed by sanding the chamber with 220 grit paper wrapped around a dowel rod. The paltry amount of cake removed is shown along with the tools used.

The paltry amount of cake removed is shown along with the tools used. A quick inspection of the chamber reveals healthy briar with no indication of heating issues.

A quick inspection of the chamber reveals healthy briar with no indication of heating issues. During the cleaning, the gold band slipped off. This will make cleaning much easier.

During the cleaning, the gold band slipped off. This will make cleaning much easier. Next, the cleaning moves to the external briar using undiluted Murphy Oil Soap and a cotton pad. The photo below shows some of the red ruby finish leeching off.

Next, the cleaning moves to the external briar using undiluted Murphy Oil Soap and a cotton pad. The photo below shows some of the red ruby finish leeching off. A brass brush helps to lightly scrub the rim to address the darkened briar from charring.

A brass brush helps to lightly scrub the rim to address the darkened briar from charring. The stummel is taken to the sink to start cleaning the internals. Using warm water, shank brushes scrub the internals with anti-oil liquid dishwashing soap. After scrubbing, the stummel is thoroughly rinsed and brought back to the table.

The stummel is taken to the sink to start cleaning the internals. Using warm water, shank brushes scrub the internals with anti-oil liquid dishwashing soap. After scrubbing, the stummel is thoroughly rinsed and brought back to the table. The internal cleaning continues. A couple of cotton buds and pipe cleaners moistened with isopropyl 99% confirm that this stummel is in good shape. It doesn’t happen often to have such a clean pipe. The Yves’ former steward had not smoked this pipe often it seems.

The internal cleaning continues. A couple of cotton buds and pipe cleaners moistened with isopropyl 99% confirm that this stummel is in good shape. It doesn’t happen often to have such a clean pipe. The Yves’ former steward had not smoked this pipe often it seems. After the cleaning of the rim, there remains a dark char ring around the back side of the inner rim edge.

After the cleaning of the rim, there remains a dark char ring around the back side of the inner rim edge. To address this, a smart bevel will be created on the inner rim edge. The wooden orb is used to provide a solid back to the sanding paper. The strips of sanding paper are pinched around the orb and inserted into the mouth of the chamber to create the bevel. With the sanding paper pinched between the edge and the orb, the orb is rotated around. The orb helps the bevel to be sharp and even.

To address this, a smart bevel will be created on the inner rim edge. The wooden orb is used to provide a solid back to the sanding paper. The strips of sanding paper are pinched around the orb and inserted into the mouth of the chamber to create the bevel. With the sanding paper pinched between the edge and the orb, the orb is rotated around. The orb helps the bevel to be sharp and even. The sanding starts with the 220 strip and followed by 320 and 600 grit strips.

The sanding starts with the 220 strip and followed by 320 and 600 grit strips. I like how the bevel looks. There’s still some darkened briar shown in the second photo, but I’m hopeful that this should not be noticed at all after the rim is touched up.

I like how the bevel looks. There’s still some darkened briar shown in the second photo, but I’m hopeful that this should not be noticed at all after the rim is touched up. Micromesh pads are applied next to clean up the stummel. I decided not to use the first 3 pads, 1500 to 2400, which are more abrasive. I like the deep ruby red finish as is and I don’t want to lighten or thin it. The micromesh pads are started with grades 3200, 3600 and 4000.

Micromesh pads are applied next to clean up the stummel. I decided not to use the first 3 pads, 1500 to 2400, which are more abrasive. I like the deep ruby red finish as is and I don’t want to lighten or thin it. The micromesh pads are started with grades 3200, 3600 and 4000. The next set of pads are grades 6000, 8000 and 12000. I like it!

The next set of pads are grades 6000, 8000 and 12000. I like it! Since the rim was cleaned more aggressively because of the darkened briar, it has lightened. The smart bevel that was created has no color to it.

Since the rim was cleaned more aggressively because of the darkened briar, it has lightened. The smart bevel that was created has no color to it. To touch up the rim and to have it match the rest of the stummel’s dark ruby red hue, I check out the color palette on the chopping board. The left column are all Fiebing’s aniline dyes and the right are dye sticks. The only contenders are the Fiebing’s Red and Oxblood Leather Dyes.

To touch up the rim and to have it match the rest of the stummel’s dark ruby red hue, I check out the color palette on the chopping board. The left column are all Fiebing’s aniline dyes and the right are dye sticks. The only contenders are the Fiebing’s Red and Oxblood Leather Dyes. The Oxblood Leather Dye is the best match, and a cotton bud is used to apply the dye to the rim.

The Oxblood Leather Dye is the best match, and a cotton bud is used to apply the dye to the rim. The comparison is a THUMBS UP! Wow, not bad! The only bummer is that there remains a small dark patch of briar from the rim charring. It appears that this will serve has his badge of honor of the past he has had moving to his future service 😊.

The comparison is a THUMBS UP! Wow, not bad! The only bummer is that there remains a small dark patch of briar from the rim charring. It appears that this will serve has his badge of honor of the past he has had moving to his future service 😊. It’s time to reunite stem and stummel. I discovered that the tenon/mortise fit is way too snug for comfort. This happens sometimes after cleaning. To remedy this, 220 grit paper is wrapped around the tenon and then rotated several times and tested again in the mortise. This is done a few times to customize a fit that’s not too snug but not too loose. After a good fit is achieved, 600 grit paper is wrapped and rotated to smooth the acrylic tenon to help with the aesthetics.

It’s time to reunite stem and stummel. I discovered that the tenon/mortise fit is way too snug for comfort. This happens sometimes after cleaning. To remedy this, 220 grit paper is wrapped around the tenon and then rotated several times and tested again in the mortise. This is done a few times to customize a fit that’s not too snug but not too loose. After a good fit is achieved, 600 grit paper is wrapped and rotated to smooth the acrylic tenon to help with the aesthetics. A good fit is achieved. Moving on.

A good fit is achieved. Moving on. Next, with a cotton cloth buffing wheel mounted on the rotary tool and with the speed set at about 40% full power, Blue Diamond compound is applied to stem and stummel.

Next, with a cotton cloth buffing wheel mounted on the rotary tool and with the speed set at about 40% full power, Blue Diamond compound is applied to stem and stummel. After applying the compound, the photo below shows the compound dust that’s generated during the compound application. This is removed by wiping the pipe with a felt cloth to prepare the pipe to receive the wax.

After applying the compound, the photo below shows the compound dust that’s generated during the compound application. This is removed by wiping the pipe with a felt cloth to prepare the pipe to receive the wax. Next, another dedicated cotton cloth buffing wheel is mounted at the same speed, carnauba wax is then applied to the pipe. After the application of wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine.

Next, another dedicated cotton cloth buffing wheel is mounted at the same speed, carnauba wax is then applied to the pipe. After the application of wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine. I haven’t forgotten the gold band! Buffing it with compound should remove very small scratching and raise the ‘bling factor’ of the band.

I haven’t forgotten the gold band! Buffing it with compound should remove very small scratching and raise the ‘bling factor’ of the band. Green compound is used with a dedicated cotton cloth wheel. The speed is left at about 40% full power, and the compound is applied to the band.

Green compound is used with a dedicated cotton cloth wheel. The speed is left at about 40% full power, and the compound is applied to the band. After the compound is applied, the band is buffed up with a microfiber cloth. The band cleaned up very nicely and is ready to be remounted onto the shank.

After the compound is applied, the band is buffed up with a microfiber cloth. The band cleaned up very nicely and is ready to be remounted onto the shank. To remount the band, a small amount of regular CA glue is placed on the end of a toothpick. The glue is then spread around the inside, middle of the band. Not much glue is used, and it’s spread in the middle so that when mounted, glue is not squeezed out.

To remount the band, a small amount of regular CA glue is placed on the end of a toothpick. The glue is then spread around the inside, middle of the band. Not much glue is used, and it’s spread in the middle so that when mounted, glue is not squeezed out. The band is carefully placed over the shank and then pressed against the table to make sure it is seated well and flush with the shank facing. The stem and stummel are reunited and given another rigorous hand buffing to raise the shine.

The band is carefully placed over the shank and then pressed against the table to make sure it is seated well and flush with the shank facing. The stem and stummel are reunited and given another rigorous hand buffing to raise the shine.

My, oh my…this Yves of St. Claude Elysee is certainly a Pipe for Christmas. Beneath the ruby red Santa Clause finish is beautiful horizontal grain culminating in bird’s eye grain on the front and back of the bowl. The gold band complemented by the gilded YStC on the stem adds a festive air and reminds us of Santa’s buttons and belt buckle. The glossy black acrylic stem completes the ensemble – Santa’s shiny boots ready to go 😊. Thank you again to the generous pipeman who donated this pipe benefiting the Daughters of Bulgaria, now called Spring of Hope. Pipeman Steve, commissioned this pipe for Christmas and will have the first opportunity to claim him to enjoy a Christmas Bowl from the Pipe Store. My final thank you is to God, who gave His Son, Jesus Christ to save broken people in a broken world. Thanks for joining me. Merry Christmas!

My, oh my…this Yves of St. Claude Elysee is certainly a Pipe for Christmas. Beneath the ruby red Santa Clause finish is beautiful horizontal grain culminating in bird’s eye grain on the front and back of the bowl. The gold band complemented by the gilded YStC on the stem adds a festive air and reminds us of Santa’s buttons and belt buckle. The glossy black acrylic stem completes the ensemble – Santa’s shiny boots ready to go 😊. Thank you again to the generous pipeman who donated this pipe benefiting the Daughters of Bulgaria, now called Spring of Hope. Pipeman Steve, commissioned this pipe for Christmas and will have the first opportunity to claim him to enjoy a Christmas Bowl from the Pipe Store. My final thank you is to God, who gave His Son, Jesus Christ to save broken people in a broken world. Thanks for joining me. Merry Christmas!

6 For to us a child is born,

to us a son is given;

and the government shall be upon his shoulder,

and his name shall be called

Wonderful Counselor, Mighty God,

Everlasting Father, Prince of Peace.

7 Of the increase of his government and of peace

there will be no end,

on the throne of David and over his kingdom,

to establish it and to uphold it

with justice and with righteousness

from this time forth and forevermore.

The zeal of the Lord of hosts will do this. (Isaiah 9:6-7)