The next pipe on the worktable is a nice-looking Apple shape that came to me from a pipe man who wished to remain anonymous. He had seen my restorations in various Facebook groups and because they also helped to support the work of the Daughters of Bulgaria, he reached out to me in 2019. My wife and I still lived in Sofia, Bulgaria, when this generous offer came. This quote from his email captured it all: “I find your pipe restoration work fascinating and your true mission inspiring.”

Here is the impressive Lot of 16 pipes that arrived in Bulgaria sent from this generous pipe man. The Apple now on the worktable is in the center of the row on the bottom. Several of these pipes are waiting for adoption in the For “Pipe Dreamer” ONLY! online collection. This Sunrise Amber Grain Vintage Briar 159 was produced in France and is the third of three pipes that got the attention of N.R. N.R. is a traveling adventurer and an expert in armaments and the history of arms. He is the editor of ‘Armax – The Journal of Contemporary Arms’ (https://www.facebook.com/armaxjournal). The first pipe N.R. commissioned in this bunch was an interesting Lillehammer GL of Norway (New Life for a Classic Lillehammer GL Super Extra 61 Made in Norway – The Pipe Steward) and the second was a Savinelli Capri Root Briar (A New Start for a Savinelli Capri Root Briar 310 Italy Cherrywood – The Pipe Steward). Both of these pipes turned out nicely.

This Sunrise Amber Grain Vintage Briar 159 was produced in France and is the third of three pipes that got the attention of N.R. N.R. is a traveling adventurer and an expert in armaments and the history of arms. He is the editor of ‘Armax – The Journal of Contemporary Arms’ (https://www.facebook.com/armaxjournal). The first pipe N.R. commissioned in this bunch was an interesting Lillehammer GL of Norway (New Life for a Classic Lillehammer GL Super Extra 61 Made in Norway – The Pipe Steward) and the second was a Savinelli Capri Root Briar (A New Start for a Savinelli Capri Root Briar 310 Italy Cherrywood – The Pipe Steward). Both of these pipes turned out nicely. Here are pictures of the Sunrise Amber Grain Apple that got N.R.’s attention:

Here are pictures of the Sunrise Amber Grain Apple that got N.R.’s attention:

The nomenclature is found on both sides of the shank and is thin in places. On the left side is stamped: SUNRISE [over] Amber Grain (in fancy cursive).

The nomenclature is found on both sides of the shank and is thin in places. On the left side is stamped: SUNRISE [over] Amber Grain (in fancy cursive).  On the right side also thin is stamped: Vintage Briar (also in fancy cursive). To the right of this is stamped ‘159’ the shape number.

On the right side also thin is stamped: Vintage Briar (also in fancy cursive). To the right of this is stamped ‘159’ the shape number.  When I originally posted the pipe, I missed the stamping indicating the COM. It was stamped with a very small print underneath the shank on the facing.

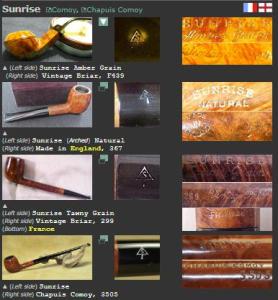

When I originally posted the pipe, I missed the stamping indicating the COM. It was stamped with a very small print underneath the shank on the facing. Pipephil’s Sunrise entry is referenced in Pipedia. Here is the Pipephil information, which is helpful identifying this pipe as a Comoy, Chapuis Comoy production (Su-Suz — Pipes: Logos & Markings (pipephil.eu)):

Pipephil’s Sunrise entry is referenced in Pipedia. Here is the Pipephil information, which is helpful identifying this pipe as a Comoy, Chapuis Comoy production (Su-Suz — Pipes: Logos & Markings (pipephil.eu)):

The Sunrise brand perfectly illustrates the split pipe production of a same label between Saint Claude (FR) and London (GB) during the period Chapuis Comoy and Comoy closely collaborated (prior to early 1970s).

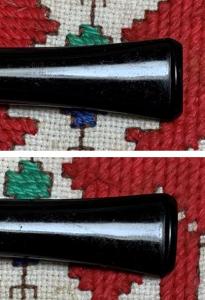

I clipped the panel of examples of Sunrise pipes and there is no doubt that the nomenclature of our Sunrise matches the examples given. The examples indicate that the Sunrise line had variations of differing grains – Amber Grain, Natural Grain, and Tawney Grain. What I also discovered from the Pipephil information is the shape of the stem logo identifying the Sunrise line – what I’m calling an upward pointing arrow with an ‘S’ in the arrowhead. I had not seen a stem logo before, but another closer look at the stem reveals the last gasps of a Sunrise logo. The only thing detectable is the vertical shaft of the arrow and a glimmer of the diagonal pitch of the arrowhead. I’m not sure this is enough to salvage at this point.

What I also discovered from the Pipephil information is the shape of the stem logo identifying the Sunrise line – what I’m calling an upward pointing arrow with an ‘S’ in the arrowhead. I had not seen a stem logo before, but another closer look at the stem reveals the last gasps of a Sunrise logo. The only thing detectable is the vertical shaft of the arrow and a glimmer of the diagonal pitch of the arrowhead. I’m not sure this is enough to salvage at this point. There are also examples of the Sunrise line in the Pipedia article (Sunrise – Pipedia). The information about Sunrise from the information above points to the two countries of origin that the Sunrise production shared. The Comoy’s of London production from Great Britain and the Chapuis Comoy production would be in Saint Claude, France. Also stated above was that:

There are also examples of the Sunrise line in the Pipedia article (Sunrise – Pipedia). The information about Sunrise from the information above points to the two countries of origin that the Sunrise production shared. The Comoy’s of London production from Great Britain and the Chapuis Comoy production would be in Saint Claude, France. Also stated above was that:

Chapuis Comoy and Comoy closely collaborated (prior to early 1970s).

This would possibly indicate that our Sunrise Amber Grain was produced prior to the 1970s as part of the Chapuis Comoy production in Saint Claude. However, the question that might derail this dating is whether after the early 1970 collaboration, did the Sunrise line continue to be produced separately? When I first read this, my sense is that the Sunrise line ended after the early 1970s, but this may not be the case.

Pipedia’s Chapuis-Comoy article is from From Pipes, Artisans and Trademarks, by Jose Manuel Lopés’ gives a good history overview from 30,000 feet (Chapuis-Comoy – Pipedia):

Chapuis-Comoy is a factory in Saint-Claude, France.

It began with Francois Comoy who, in 1825, was making pipes in boxwood and other types, as well as clay pipes, for the armies of Napoleon. In 1856, the Comoy factory was the first to produce briar bowls at Saint-Claude. In 1870, Francois’s grandson, Henri Comoy (1850-1924) was taken prisoner in Switzerland whilst serving in the French army during the Franco-Prussian war, where he found his cousins, the Chapuis. This meeting produced the idea of an association, which only became a reality in 1922, with the creation of Chapuis-Comoy. After Henri’s death, his sons Paul and Adrien, took over the company with the support of their cousins, Emile and Louis Chapuis Sr., and in 1928 they created the Chacom brand.

In 1932, due to the economic crisis at Saint-Claude, the factory merged with La Bruyère, adopting that name, and becoming one of the biggest pipe companies in the world, with 450 workers. Louis Chapuis Jr., joined the company in 1938 and Pierre Comoy in 1947. The name Chapuis-Comoy returned in 1957 (125 workers), due to the success of the Chacom brand in France. In 1971, the London factory (see Comoy’s) became independent, and Yves Grenard, second cousin to Pierre, took over Saint-Claude, and is still running it. Between 1987 and 2001, the factory, which employed over 40 people, joined the Cuty-Fort Enterprises SA holding and, in 1994, included the Ropp brand in its catalog.

From the Lopes information, we may have the underlying reason for the end of the close collaboration between the French and English Comoy houses in the early1970s. Lopes says:

In 1971, the London factory became independent, and Yves Grenard, second cousin to Pierre, took over the Saint-Claude, and is still running it.

The Pipedia article also has a great period ad from Comoy’s of London showing the Sunrise along with their other offerings. Unfortunately, there is no date attached to the ad. The fine print for the Sunrise is:

The fine print for the Sunrise is:

Virgin briar, precision made from century-old Algerian briar, thoroughly cured for mellow sweetness.

I tend to lean toward the pre-1970 dating explanation of this Chapuis-Comoy Sunrise, but we can’t bet the farm on this without further research.

With a better understanding of the Chapuis-Comoy Sunrise Amber Grain Vintage Briar Apple on the worktable, I take a closer look at the issues. The chamber has a light cake build up which will be cleared to allow fresh briar to emerge. The rounded rim has some burn marks. One on the front and a batch on the back.

The rounded rim has some burn marks. One on the front and a batch on the back. There is also what looks like a small fill on the aft side of the bowl. This will be looked at more closely after the cleaning.

There is also what looks like a small fill on the aft side of the bowl. This will be looked at more closely after the cleaning. Over the surface of the bowl, there are nicks and dents which are normal wear and tear.

Over the surface of the bowl, there are nicks and dents which are normal wear and tear. The flat heel has some old fills too that need to be looked at.

The flat heel has some old fills too that need to be looked at. The stem is in great shape. I see no oxidation in the vulcanite. It looks like this pipe has been in a drawer. The picture shows roughness which is on the bit and sporadically over the stem. The upper bit has a very soft compression which would not show in the picture.

The stem is in great shape. I see no oxidation in the vulcanite. It looks like this pipe has been in a drawer. The picture shows roughness which is on the bit and sporadically over the stem. The upper bit has a very soft compression which would not show in the picture.  To begin the restoration of this Sunrise, the stem’s airway is cleaned with one pipe cleaner moistened with isopropyl 99% alcohol.

To begin the restoration of this Sunrise, the stem’s airway is cleaned with one pipe cleaner moistened with isopropyl 99% alcohol. Even though I see no oxidation, the stem will soak for a bit in Briarville’s Pipe Stem Oxidation Remover just to make sure.

Even though I see no oxidation, the stem will soak for a bit in Briarville’s Pipe Stem Oxidation Remover just to make sure. Moving now to the stummel, a picture of the chamber shows a light cake buildup.

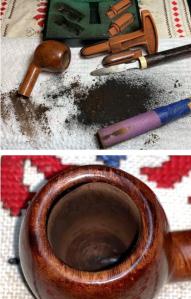

Moving now to the stummel, a picture of the chamber shows a light cake buildup.  To ream the chamber, 2 of the 4 blade heads available in the Pipnet Reaming Kit are used.

To ream the chamber, 2 of the 4 blade heads available in the Pipnet Reaming Kit are used. To fine tune the reaming, the chamber is also scraped using the Savinelli Fitsall Tool.

To fine tune the reaming, the chamber is also scraped using the Savinelli Fitsall Tool. Finally, to fully clear the chamber of carbon residue, the chamber is sanded with 220 grit paper wrapped around a dowel rod.

Finally, to fully clear the chamber of carbon residue, the chamber is sanded with 220 grit paper wrapped around a dowel rod. The full set of tools is shown, and an inspection of the chamber walls reveal no heating damage or issues.

The full set of tools is shown, and an inspection of the chamber walls reveal no heating damage or issues. Continuing with the cleaning on the external briar, undiluted Murphy Oil Soap is used scrubbing with a cotton pad. The brass brush also works on the dark spots on the rim.

Continuing with the cleaning on the external briar, undiluted Murphy Oil Soap is used scrubbing with a cotton pad. The brass brush also works on the dark spots on the rim. After scrubbing, the stummel is taken to the sink where shank brushes are used to scrub the internals with warm water and anti-oil liquid dishwashing soap.

After scrubbing, the stummel is taken to the sink where shank brushes are used to scrub the internals with warm water and anti-oil liquid dishwashing soap.  After a thorough rinsing the stummel returns to the worktable.

After a thorough rinsing the stummel returns to the worktable. The cleaning continues with the internals using cotton buds and pipe cleaners. A small dental spoon also scrapes the mortise walls bringing out tars and oils. After a time, the buds emerge lighter, and the cleaning is complete.

The cleaning continues with the internals using cotton buds and pipe cleaners. A small dental spoon also scrapes the mortise walls bringing out tars and oils. After a time, the buds emerge lighter, and the cleaning is complete. With the basic cleaning completed, I take a closer look at the stummel. The rim has char spots on the front and back side of the rim. The cleaning helped a good deal using the brass brush, but there remains some shadows and spots.

With the basic cleaning completed, I take a closer look at the stummel. The rim has char spots on the front and back side of the rim. The cleaning helped a good deal using the brass brush, but there remains some shadows and spots. In both the picture above and below, the inner rim has a black ring which needs to be addressed.

In both the picture above and below, the inner rim has a black ring which needs to be addressed. Using 220 grit paper, the rounded rim is lightly sanded just enough to erase the blemishes. Since the rim is rounded, it is not difficult to sand. Both the inner ring and char marks are removed.

Using 220 grit paper, the rounded rim is lightly sanded just enough to erase the blemishes. Since the rim is rounded, it is not difficult to sand. Both the inner ring and char marks are removed.  The 220 paper is followed with the finer 320 grit paper to further smooth the rim. This is followed by applying 600 grit paper.

The 220 paper is followed with the finer 320 grit paper to further smooth the rim. This is followed by applying 600 grit paper.  The rim looks great. Looking at other issues that surfaced after the cleaning, there are small fills that caught my eye. The largest is on the back of the bowl just beneath the rim. The other very small fill was on the front lower side of the bowl. Then, there were also 3 fills needing attention on the flat heel.

The rim looks great. Looking at other issues that surfaced after the cleaning, there are small fills that caught my eye. The largest is on the back of the bowl just beneath the rim. The other very small fill was on the front lower side of the bowl. Then, there were also 3 fills needing attention on the flat heel.

Using a sharp dental probe, each old fill material in each pit is dug out.

Using a sharp dental probe, each old fill material in each pit is dug out.

Next, after wiping the repair areas with alcohol, each pit is filled with Amber Medium CA glue. To hold each patch in place while moving to work on others, an accelerator is sprayed onto the patch to cure the patch more rapidly.

Next, after wiping the repair areas with alcohol, each pit is filled with Amber Medium CA glue. To hold each patch in place while moving to work on others, an accelerator is sprayed onto the patch to cure the patch more rapidly.

The stummel is put aside for the time to allow the patches to cure thoroughly. The stem has been soaking in Briarville.com ‘Pipe Stem Oxidation Remover’. After the stem is removed from the soak, it is rubbed vigorously with a cloth to remove any raised oxidation. A pipe cleaner moistened with isopropyl 99% clears the Oxidation Remover fluid from the airway.

The stummel is put aside for the time to allow the patches to cure thoroughly. The stem has been soaking in Briarville.com ‘Pipe Stem Oxidation Remover’. After the stem is removed from the soak, it is rubbed vigorously with a cloth to remove any raised oxidation. A pipe cleaner moistened with isopropyl 99% clears the Oxidation Remover fluid from the airway. Pictures prove unhelpful seeing the small compressions I can see on the upper and lower bit. The stem overall has no oxidation left over, but there are minute marks and scratches that need to be sanded. To start, 220 grit paper is used to smooth the bit – upper and lower.

Pictures prove unhelpful seeing the small compressions I can see on the upper and lower bit. The stem overall has no oxidation left over, but there are minute marks and scratches that need to be sanded. To start, 220 grit paper is used to smooth the bit – upper and lower. With the small nicks and scratches over the stem, the sanding is expanded to the entire stem using 320 grit paper – upper and lower. Throughout the sanding of the stem, I give the ghosted Sunrise stem logo plenty of leigh way. If the logo is disappearing into history, I don’t want to help it along. A plastic disk is also used to protect the stem facing from shouldering over the edges.

With the small nicks and scratches over the stem, the sanding is expanded to the entire stem using 320 grit paper – upper and lower. Throughout the sanding of the stem, I give the ghosted Sunrise stem logo plenty of leigh way. If the logo is disappearing into history, I don’t want to help it along. A plastic disk is also used to protect the stem facing from shouldering over the edges. Next, the stem is wet sanded with 600 grit paper, and this is followed by applying 0000 grade steel wool.

Next, the stem is wet sanded with 600 grit paper, and this is followed by applying 0000 grade steel wool. The sanding now transitions more to polishing using 9 micromesh pads. Each of the pads dry sand the stem first using pads 1500, 1800 and 2400. Following this are pads 3200, 3800, and 4000. Finally, pads 6000, 8000, and 12000 are applied to the stem. After each pad, Obsidian Oil is applied to the stem. Obsidian Oil helps to protect the vulcanite from oxidation, and it helps condition the stem. With the last set of 3 pads, the entire stem was sanded including the logo patch. These pads have negligible abrasion and are polishing at this point in the process. This helps to blend the logo patch as well. The stem looks great.

The sanding now transitions more to polishing using 9 micromesh pads. Each of the pads dry sand the stem first using pads 1500, 1800 and 2400. Following this are pads 3200, 3800, and 4000. Finally, pads 6000, 8000, and 12000 are applied to the stem. After each pad, Obsidian Oil is applied to the stem. Obsidian Oil helps to protect the vulcanite from oxidation, and it helps condition the stem. With the last set of 3 pads, the entire stem was sanded including the logo patch. These pads have negligible abrasion and are polishing at this point in the process. This helps to blend the logo patch as well. The stem looks great.

The stem looks great and to polish it further, Mark Hoover’s ‘Before & After’ Fine and Extra Fine Polishes are used. After putting a small amount of Fine Polish on the finger, the polish is worked into the vulcanite stem. Afterwards, the excess is wiped with a paper towel. The same process is done with the Extra Fine Polish.

The stem looks great and to polish it further, Mark Hoover’s ‘Before & After’ Fine and Extra Fine Polishes are used. After putting a small amount of Fine Polish on the finger, the polish is worked into the vulcanite stem. Afterwards, the excess is wiped with a paper towel. The same process is done with the Extra Fine Polish.  Mark’s polishes do a good job shining and conditioning the stem.

Mark’s polishes do a good job shining and conditioning the stem. Switching again to the stummel, the patches that were done are fully cured. Starting with the larger one on the back side of the bowl, the patch mound is filed down with needle files to bring the mound flush with the briar surface. I try to stay on top of the mound as much as possible.

Switching again to the stummel, the patches that were done are fully cured. Starting with the larger one on the back side of the bowl, the patch mound is filed down with needle files to bring the mound flush with the briar surface. I try to stay on top of the mound as much as possible. Next, the patch is sanded first with 220 paper then 600 grit paper.

Next, the patch is sanded first with 220 paper then 600 grit paper. The same steps are done with each patch. Next, filing and sanding commences with the patch on the lower front of the bowl.

The same steps are done with each patch. Next, filing and sanding commences with the patch on the lower front of the bowl. Finally, the 3 patches on the flat heal are filed and sanded.

Finally, the 3 patches on the flat heal are filed and sanded. After finishing the patches, the entire stummel is sanded with sanding sponges to remove the small scratches and dings. I’m careful to avoid the thinning nomenclature on both sides of the shank and the COM on the underside of the shank. Only the medium, light and fine sponges are used.

After finishing the patches, the entire stummel is sanded with sanding sponges to remove the small scratches and dings. I’m careful to avoid the thinning nomenclature on both sides of the shank and the COM on the underside of the shank. Only the medium, light and fine sponges are used. Continuing with the stummel, micromesh pads are used in sets of three. Between each pad the stummel is wiped with a moist cloth to remove dust and to give the next pad more traction. The nomenclature on the shank is avoided until halfway through and then micromesh pads were applied. First, 1500, 1800 and 2400.

Continuing with the stummel, micromesh pads are used in sets of three. Between each pad the stummel is wiped with a moist cloth to remove dust and to give the next pad more traction. The nomenclature on the shank is avoided until halfway through and then micromesh pads were applied. First, 1500, 1800 and 2400.  Next, pads 3200, 3600, and 4000 were used.

Next, pads 3200, 3600, and 4000 were used. Finally, pads 6000, 8000, and 12000 were applied.

Finally, pads 6000, 8000, and 12000 were applied. The stummel is looking great. To bring out the natural hues of the grain, Mark Hoover’s ‘Before & After’ Restoration Balm is used. After putting some Balm on the finger, the Balm is worked into the briar. When this has been done thoroughly, the stummel is set to the side for about 10 minutes to allow the Balm to be absorbed.

The stummel is looking great. To bring out the natural hues of the grain, Mark Hoover’s ‘Before & After’ Restoration Balm is used. After putting some Balm on the finger, the Balm is worked into the briar. When this has been done thoroughly, the stummel is set to the side for about 10 minutes to allow the Balm to be absorbed. A dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the briar. I often use this cloth to spruce up pipes in my own collection.

A dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the briar. I often use this cloth to spruce up pipes in my own collection. Now, the home stretch. The stem and stummel are reunited and a cotton cloth buffing wheel is mounted onto the rotary tool. With the speed at about 40% full power, Blue Diamond compound is applied to the pipe.

Now, the home stretch. The stem and stummel are reunited and a cotton cloth buffing wheel is mounted onto the rotary tool. With the speed at about 40% full power, Blue Diamond compound is applied to the pipe. After the application of the compound, the pipe is covered with compound dust. A felt cloth is used to wipe off the dust in preparation for the wax.

After the application of the compound, the pipe is covered with compound dust. A felt cloth is used to wipe off the dust in preparation for the wax. With another cotton cloth wheel mounted at the same speed, Carnauba wax is applied to the pipe. After the application, the pipe is given a rigorous hand buffing to remove the excess wax and to raise the shine.

With another cotton cloth wheel mounted at the same speed, Carnauba wax is applied to the pipe. After the application, the pipe is given a rigorous hand buffing to remove the excess wax and to raise the shine. My thanks goes to the generous pipe man who donated this pipe to benefit the Daughters of Bulgaria. Thanks! I enjoyed learning about the provenance of this Sunshine Amber Grain Briar and its relationship with the French pipe manufacturer, Chapuis Comoy. It’s possible that this Sunrise’s production predates the early 1970s and if it does, it’s in great shape. The Apple shape is elegant with the curves and lines. The grain on this pipe emerged nicely with a great batch of bird’s eye. The dimensions are Length: 5 13/16 inches, Height: 7/8 inches, Rim width: 1 1/16 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/4 inches. This is the 3rd of 3 pipes that N.R. has commissioned and as the commissioner, he has the first opportunity to claim the Sunrise from the Pipe Steward Store. A large portion of the proceeds benefit the work of the Daughters of Bulgaria (now called, Spring of Hope) helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

My thanks goes to the generous pipe man who donated this pipe to benefit the Daughters of Bulgaria. Thanks! I enjoyed learning about the provenance of this Sunshine Amber Grain Briar and its relationship with the French pipe manufacturer, Chapuis Comoy. It’s possible that this Sunrise’s production predates the early 1970s and if it does, it’s in great shape. The Apple shape is elegant with the curves and lines. The grain on this pipe emerged nicely with a great batch of bird’s eye. The dimensions are Length: 5 13/16 inches, Height: 7/8 inches, Rim width: 1 1/16 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/4 inches. This is the 3rd of 3 pipes that N.R. has commissioned and as the commissioner, he has the first opportunity to claim the Sunrise from the Pipe Steward Store. A large portion of the proceeds benefit the work of the Daughters of Bulgaria (now called, Spring of Hope) helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Those Sunrise pipes always seem to have a nice glow, good job!

LikeLiked by 1 person

Thanks, Al. It shaped up nicely and I enjoyed drilling down in the provenance as well.

LikeLike