After some time, I’m finally back to the worktable. The detour from the worktable came in the form of driving a 26’ U-Haul truck from Golden, Colorado, to Mission Viejo, California. My wife and I helped our daughter, and her family make the move to sunny Southern California where our son in law found a new job. Mission Viejo is just south of LA and yes, the fires were burning when we arrived. We experienced smoky days but thankfully, no fires. A tragic occurrence to the people of California. As my daughter passed to the left, my wife took this picture of me Uhauling down the road somewhere in Utah. Yes, you can see me in the mirror reflection. During our time there, we didn’t unpack the whole time. We were able to go down and see the peaceful Pacific Ocean at the beach. With much gratitude for the patience of pipemen who have pipes waiting in the queue, the next pipe on the worktable is an unbranded slightly bent rusticated Volcano. It comes from what I have called the Lot of 68 which I acquired from a seller in West Hartford, Connecticut. Many treasures have been commissioned from this Lot benefitting the Daughters of Bulgaria, now called Spring of Hope. The Unbranded Volcano came with two others with the same unique ‘Seahorse’ sculpted finish. The other two were also commissioned from the For “Pipe Dreamers” ONLY! online collection and are patiently waiting in the queue. This is the picture the West Hartford seller provided. The pipe now on the table is the first of the 3.

With much gratitude for the patience of pipemen who have pipes waiting in the queue, the next pipe on the worktable is an unbranded slightly bent rusticated Volcano. It comes from what I have called the Lot of 68 which I acquired from a seller in West Hartford, Connecticut. Many treasures have been commissioned from this Lot benefitting the Daughters of Bulgaria, now called Spring of Hope. The Unbranded Volcano came with two others with the same unique ‘Seahorse’ sculpted finish. The other two were also commissioned from the For “Pipe Dreamers” ONLY! online collection and are patiently waiting in the queue. This is the picture the West Hartford seller provided. The pipe now on the table is the first of the 3. Pipeman Aaron reached out to me after the Rusticated Volcano got his attention. What I discovered about Aaron is something I appreciate deeply. Not only do I appreciate that Aaron is a father of 3 children and 4 grandchildren, but I discovered that he is a Criminal Investigator in West Tennessee working for a city police department. In our communications, I discovered that he oversees all child abuse and sex crimes involving children. This vocation and focus connected him immediately with our support of the Daughters of Bulgaria. When my wife and I were in Bulgaria working with the Daughters, we were heart-sickened for the children we encountered on the streets of Bulgaria selling themselves. My appreciation for Aaron’s vocation and the difficulty of seeing the abuse of children runs deep. On the lighter side, I discovered that Aaron loves the outdoors, collects pipes and even has tried his hand at crafting a pipe. Lastly, Aaron describes himself as an old firearms hobbyist. I appreciate learning about the new stewards of the pipes I restore. Here are pictures of the Unbranded Rusticated Volcano that got Aaron’s attention.

Pipeman Aaron reached out to me after the Rusticated Volcano got his attention. What I discovered about Aaron is something I appreciate deeply. Not only do I appreciate that Aaron is a father of 3 children and 4 grandchildren, but I discovered that he is a Criminal Investigator in West Tennessee working for a city police department. In our communications, I discovered that he oversees all child abuse and sex crimes involving children. This vocation and focus connected him immediately with our support of the Daughters of Bulgaria. When my wife and I were in Bulgaria working with the Daughters, we were heart-sickened for the children we encountered on the streets of Bulgaria selling themselves. My appreciation for Aaron’s vocation and the difficulty of seeing the abuse of children runs deep. On the lighter side, I discovered that Aaron loves the outdoors, collects pipes and even has tried his hand at crafting a pipe. Lastly, Aaron describes himself as an old firearms hobbyist. I appreciate learning about the new stewards of the pipes I restore. Here are pictures of the Unbranded Rusticated Volcano that got Aaron’s attention.

The only information regarding the provenance of this Seahorse sculpted Volcano is the COM: ITALY.

The only information regarding the provenance of this Seahorse sculpted Volcano is the COM: ITALY. There’s not a lot to go on to determine which manufacturer in Italy produced this eye-catching line of pipes. As I first eyeballed the 3 Seahorse finished pipes – two Volcanos and a Dublin, the Italian maker Lorenzo came to mind. I wrote to Steve at RebornPipes to see if he had any ideas about who possibly could have manufactured these pipes. I was gratified when he also suggested that Lorenzo might be the name. I have worked on Lorenzo pipes before, and they all bore witness to Lorenzo’s reputation for creating pipe shapes and designs on the ‘edge’. Here are a few examples: First, Breathing New Life into an ‘Elegant’ Lorenzo Eleganza 8769 of Italy Bent Dublin – The Pipe Steward.

There’s not a lot to go on to determine which manufacturer in Italy produced this eye-catching line of pipes. As I first eyeballed the 3 Seahorse finished pipes – two Volcanos and a Dublin, the Italian maker Lorenzo came to mind. I wrote to Steve at RebornPipes to see if he had any ideas about who possibly could have manufactured these pipes. I was gratified when he also suggested that Lorenzo might be the name. I have worked on Lorenzo pipes before, and they all bore witness to Lorenzo’s reputation for creating pipe shapes and designs on the ‘edge’. Here are a few examples: First, Breathing New Life into an ‘Elegant’ Lorenzo Eleganza 8769 of Italy Bent Dublin – The Pipe Steward. My Final Restoration from Bulgaria – A Find in Athens: Refreshing a Fun Lorenzo Carnevale San Remo Italy 8672 Apple | rebornpipes

My Final Restoration from Bulgaria – A Find in Athens: Refreshing a Fun Lorenzo Carnevale San Remo Italy 8672 Apple | rebornpipes This Lorenzo (Ria_io Selection Italy Full Bent Billiard | rebornpipes) is special. I restored it and gave it to my son, James, several years ago. I love the Oom Paul Egg shape and the blasted finish was exemplary.

This Lorenzo (Ria_io Selection Italy Full Bent Billiard | rebornpipes) is special. I restored it and gave it to my son, James, several years ago. I love the Oom Paul Egg shape and the blasted finish was exemplary. Pipephil.eu has a info panel devoted to Lorenzo (Lor-Lt — Pipes : Logos & Markings) providing the rough history of the name and a few examples to underscore the reputation of ‘edgy’ pipes.

Pipephil.eu has a info panel devoted to Lorenzo (Lor-Lt — Pipes : Logos & Markings) providing the rough history of the name and a few examples to underscore the reputation of ‘edgy’ pipes. A fuller discourse of the Lorenzo name can be found at Pipedia (Lorenzo – Pipedia) with more pictures of Lorenzo pipes. I can’t say with any certainty that the ‘Seahorse’ finish Volcano on the table is from Lorenzo, but this pipe and his brothers in the queue certainly jump out and get your attention with the rusticated ‘Seahorse’ finish.

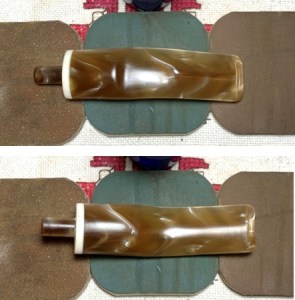

A fuller discourse of the Lorenzo name can be found at Pipedia (Lorenzo – Pipedia) with more pictures of Lorenzo pipes. I can’t say with any certainty that the ‘Seahorse’ finish Volcano on the table is from Lorenzo, but this pipe and his brothers in the queue certainly jump out and get your attention with the rusticated ‘Seahorse’ finish. It would be an overstatement to describe this project as a full restoration project. The pipe is in good condition and in need of basic cleaning, sanding and polishing. The chamber has a moderate layer of cake which will be removed to allow fresh briar to emerge. The honey marmalade acrylic stem is attractive and shows almost no biting on the bit. To begin the refreshing of the rusticated Seahorse Volcano, the chamber is cleared of the carbon cake. A starting picture will mark the progress.

It would be an overstatement to describe this project as a full restoration project. The pipe is in good condition and in need of basic cleaning, sanding and polishing. The chamber has a moderate layer of cake which will be removed to allow fresh briar to emerge. The honey marmalade acrylic stem is attractive and shows almost no biting on the bit. To begin the refreshing of the rusticated Seahorse Volcano, the chamber is cleared of the carbon cake. A starting picture will mark the progress. To ream the chamber, the Pipnet Reaming Kit is used. 3 of the 4 blades available are utilized.

To ream the chamber, the Pipnet Reaming Kit is used. 3 of the 4 blades available are utilized. Following the reaming, the chamber walls are scraped using the Savinelli Fitsall Tool. The Tool can reach into the sharp angles at the floor of the chamber to remove this hard-to-get carbon cake.

Following the reaming, the chamber walls are scraped using the Savinelli Fitsall Tool. The Tool can reach into the sharp angles at the floor of the chamber to remove this hard-to-get carbon cake. Finally, the vestiges of cake are removed by sanding the chamber with 220 paper wrapped around a dowel rod.

Finally, the vestiges of cake are removed by sanding the chamber with 220 paper wrapped around a dowel rod. The full arsenal of tools is shown, and a quick inspection shows healthy briar with no heating issues.

The full arsenal of tools is shown, and a quick inspection shows healthy briar with no heating issues. The cleaning now moves to the external sculpted surface. There’s grime in the crevasses of the deep rustication. A few pictures show the starting point.

The cleaning now moves to the external sculpted surface. There’s grime in the crevasses of the deep rustication. A few pictures show the starting point. A cotton pad is bypassed, and the rough surface of the bowl is scrubbed with Murphy Oil Soap and a bristled toothbrush to dig into the nooks and crannies.

A cotton pad is bypassed, and the rough surface of the bowl is scrubbed with Murphy Oil Soap and a bristled toothbrush to dig into the nooks and crannies. The rim has a crusty lava flow over it, and this is a bit of a challenge with the sculpted rim surface. A brass wire brush is used for this. The brass brush lends some muscle to the cleaning without damaging the briar.

The rim has a crusty lava flow over it, and this is a bit of a challenge with the sculpted rim surface. A brass wire brush is used for this. The brass brush lends some muscle to the cleaning without damaging the briar. The tip of the Savinelli Fitsall Tool is also used to scrape the lava crust in the crevasses.

The tip of the Savinelli Fitsall Tool is also used to scrape the lava crust in the crevasses. The cleaning continues at the utility sink. The internals are scrubbed with shank brushes, warm water and anti-oil liquid dishwashing soap.

The cleaning continues at the utility sink. The internals are scrubbed with shank brushes, warm water and anti-oil liquid dishwashing soap. After the scrubbing, the stummel is rinsed thoroughly and returned to the worktable.

After the scrubbing, the stummel is rinsed thoroughly and returned to the worktable. More focused cleaning continues with the internals using isopropyl 99% alcohol and cotton buds. A small dental tool is also used to scrape the mortise walls to remove tar and oil.

More focused cleaning continues with the internals using isopropyl 99% alcohol and cotton buds. A small dental tool is also used to scrape the mortise walls to remove tar and oil. After the cleaning of the rim, the finish has lightened on some of the high spots. To touch up the rim a dye stick is used.

After the cleaning of the rim, the finish has lightened on some of the high spots. To touch up the rim a dye stick is used. After checking out a few sticks, the Burnt Sienna matched very nicely with the existing hue.

After checking out a few sticks, the Burnt Sienna matched very nicely with the existing hue. I’ve been looking forward to the next step applying Mark Hoover’s ‘Before & After’ Restoration Balm to the sculpted surface. The Balm does a good job bringing out the natural hues of the briar and deepening the appearance of the finish. After placing some of the Balm on my finger, the Balm is applied to the entire surface. It took some time to push and spread the Balm over the deep crevasses so that it was evenly spread and not collecting in crevasses. After the Balm was effectively applied, the stummel was set aside for about 10 minutes to allow the Balm to be absorbed.

I’ve been looking forward to the next step applying Mark Hoover’s ‘Before & After’ Restoration Balm to the sculpted surface. The Balm does a good job bringing out the natural hues of the briar and deepening the appearance of the finish. After placing some of the Balm on my finger, the Balm is applied to the entire surface. It took some time to push and spread the Balm over the deep crevasses so that it was evenly spread and not collecting in crevasses. After the Balm was effectively applied, the stummel was set aside for about 10 minutes to allow the Balm to be absorbed. After the time elapses, the stummel is rigorously wiped and buffed with a dedicated microfiber cloth to remove the excess Balm. I like the results.

After the time elapses, the stummel is rigorously wiped and buffed with a dedicated microfiber cloth to remove the excess Balm. I like the results. Turning next to the stem, the airway is stained and darker than the surrounding acrylic marbling.

Turning next to the stem, the airway is stained and darker than the surrounding acrylic marbling. To address the staining, bristled and regular pipe cleaners are used using isopropyl 99% alcohol. Soft Scrub is also used with its bleach base. A lot of scrubbing made significant progress with the stem’s airway.

To address the staining, bristled and regular pipe cleaners are used using isopropyl 99% alcohol. Soft Scrub is also used with its bleach base. A lot of scrubbing made significant progress with the stem’s airway. There is very little biting damage on the bit, but there is some roughness. 220 grit paper is used to clean this up.

There is very little biting damage on the bit, but there is some roughness. 220 grit paper is used to clean this up. The sanding is next expanded to the entire stem using 320 grit paper.

The sanding is next expanded to the entire stem using 320 grit paper. 600 grit paper is then used to wet sand the stem and this is followed by applying 0000 steel wool.

600 grit paper is then used to wet sand the stem and this is followed by applying 0000 steel wool. The sanding transitions from sanding to polishing with micromesh pads. Between each pad, Obsidian Oil is applied to the stem. First, pads 1500, 1800 and 2400 are used.

The sanding transitions from sanding to polishing with micromesh pads. Between each pad, Obsidian Oil is applied to the stem. First, pads 1500, 1800 and 2400 are used. Next, pads 3200, 3600 and 4000 are used.

Next, pads 3200, 3600 and 4000 are used. Finally, pads 6000, 8000 and 12000 are used. The ‘fire’ of the acrylic pops and looks great.

Finally, pads 6000, 8000 and 12000 are used. The ‘fire’ of the acrylic pops and looks great. Next, with the stem and stummel reunited, Blue Diamond compound – a fine abrasive, is used on the acrylic stem as well as on the smooth briar panel on the shank’s underside and the smooth ring around the shank facing. The compound is not applied to the rusticated surface. Why? The compound dust would really muck up the rustication getting lodged in the crevasses. It would be a bear to clean. A cotton cloth buffing wheel is mounted on the rotary tool, and with the speed set at about 40% full power, the compound is applied.

Next, with the stem and stummel reunited, Blue Diamond compound – a fine abrasive, is used on the acrylic stem as well as on the smooth briar panel on the shank’s underside and the smooth ring around the shank facing. The compound is not applied to the rusticated surface. Why? The compound dust would really muck up the rustication getting lodged in the crevasses. It would be a bear to clean. A cotton cloth buffing wheel is mounted on the rotary tool, and with the speed set at about 40% full power, the compound is applied. To remove the compound dust in preparation for the application of the wax, a felt cloth is used.

To remove the compound dust in preparation for the application of the wax, a felt cloth is used. Finally, with another dedicated cotton cloth buffing wheel mounted, carnauba wax is applied to the entire pipe. When applying wax to the rustication, a very light application is used so that wax does not get compacted into the crevasses. After applying the wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove excess wax and to raise the shine.

Finally, with another dedicated cotton cloth buffing wheel mounted, carnauba wax is applied to the entire pipe. When applying wax to the rustication, a very light application is used so that wax does not get compacted into the crevasses. After applying the wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove excess wax and to raise the shine. Even though this Italian made pipe is unbranded, the rusticated Seahorse finish is eye-catching. The Volcano bowl rests nicely in the palm and the honey marmalade acrylic stem complements nicely with its slight bend. Aaron commissioned the pipe and will have the first opportunity to claim him from the Pipe Steward Store. A portion of the proceeds of the pipes restored benefit the Daughters of Bulgaria – now called, Spring of Hope, helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Even though this Italian made pipe is unbranded, the rusticated Seahorse finish is eye-catching. The Volcano bowl rests nicely in the palm and the honey marmalade acrylic stem complements nicely with its slight bend. Aaron commissioned the pipe and will have the first opportunity to claim him from the Pipe Steward Store. A portion of the proceeds of the pipes restored benefit the Daughters of Bulgaria – now called, Spring of Hope, helping women and girls who have been trafficked and sexually exploited. Thanks for joining me!

Please pray for the people of Ukraine. We have many dear friends there who only want to be free and able to raise their children without fear.

Please pray for the people of Ukraine. We have many dear friends there who only want to be free and able to raise their children without fear.