The next pipe on the worktable was the second commission of pipeman Bill from the state of Georgia who works as a Control System Engineer contracted to the Department of Energy. Bill has commissioned a few other pipes from me, but the last was a challenge. I named the write up accurately because of the hurdles needed to bring a Big-Ben back to life: A Big-Ben Crosley Trifecta: A Blocked Airway, a Hole in the Heel and an Acrylic Shank Extension Rebuild. The Big-Ben survived and turned out great. Bill’s second commission also hails from Holland, a very sharp Amphora X-tra 732 Blasted Pickaxe. The Pickaxe came to me in what I have called the Lot of 68 which I acquired in February 2019 from a seller in West Hartford, Connecticut. The Lot of 68 found its way to the ‘For “Pipe Dreamers” ONLY!’ online collection where these pipes can be commissioned benefiting the Daughters of Bulgaria (now called, Spring of Hope) a ministry my wife and I co-founded when we lived in Bulgaria helping women and girls who had been trafficked and sexually exploited. The Amphora is circled in the picture of the Lot of 65 below.

Bill’s second commission also hails from Holland, a very sharp Amphora X-tra 732 Blasted Pickaxe. The Pickaxe came to me in what I have called the Lot of 68 which I acquired in February 2019 from a seller in West Hartford, Connecticut. The Lot of 68 found its way to the ‘For “Pipe Dreamers” ONLY!’ online collection where these pipes can be commissioned benefiting the Daughters of Bulgaria (now called, Spring of Hope) a ministry my wife and I co-founded when we lived in Bulgaria helping women and girls who had been trafficked and sexually exploited. The Amphora is circled in the picture of the Lot of 65 below. The dimensions of the Pickaxe are comfortable: Length: 5 7/16 inches, Height: 2 inches, Rim width: 1 1/4 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/2 inches. Here are pictures of Bill’s next commission.

The dimensions of the Pickaxe are comfortable: Length: 5 7/16 inches, Height: 2 inches, Rim width: 1 1/4 inches, Chamber width: 3/4 inches, Chamber depth: 1 1/2 inches. Here are pictures of Bill’s next commission.

The nomenclature is stamped on the underside smooth briar panel: GENUINE BRIAR [over] AMPHORA – HOLLAND.

The nomenclature is stamped on the underside smooth briar panel: GENUINE BRIAR [over] AMPHORA – HOLLAND. To the right of this, is stamped again, AMPHORA [over] X-tra 732.

To the right of this, is stamped again, AMPHORA [over] X-tra 732. The Amphora stem logo, a pressed circled A is stamped on the left side of the stem saddle.

The Amphora stem logo, a pressed circled A is stamped on the left side of the stem saddle. Like Bill’s first commission, the Big-Ben and this Amphora X-tra were both produced by the Elbert Gubbels & Sons B.V. company. Here is what Pipedia says about the Amphora line of Gubbels & Sons (Amphora – Pipedia):

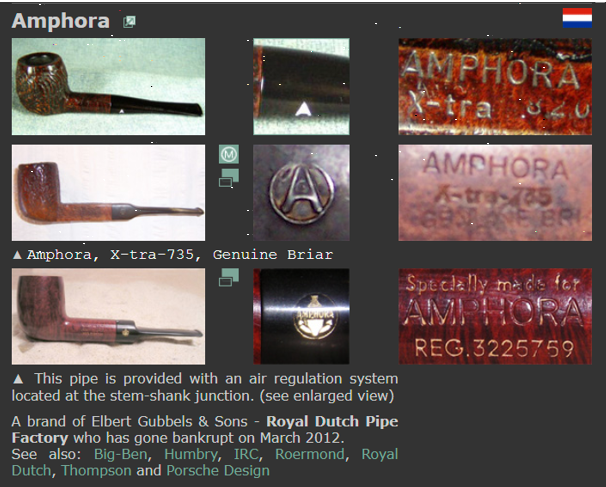

Like Bill’s first commission, the Big-Ben and this Amphora X-tra were both produced by the Elbert Gubbels & Sons B.V. company. Here is what Pipedia says about the Amphora line of Gubbels & Sons (Amphora – Pipedia):

Amphora pipes are made in Holland by the Jos. Gubbels organization. The pipes are produced in relatively small numbers to a high standard and not commonly found. They were used primarily in promotions and incentives for Amphora tobacco.

The Royal Dutch Pipe Factory Elbert Gubbels & Sons B.V. is the only manufacturer of briarroot tobacco pipes in the Benelux countries where pipes of high quality are made under the brands Big Ben, Hilson, Royal Dutch and Amphora. They also supply numerous smokers’ accessories of high quality.

The Pipedia article also included an Amphora X-tra shapes chart (Amphora Shape Chart, courtesy Doug Valitchka) which unfortunately does not include our 732 Pickaxe, but it provides a good idea what the Amphora, better quality, lineup was. Interestingly, the shape 728 on the right is like our Pickaxe and is called the Copenhagen. Pipephil.eu also has a panel devoted to Amphora pipes with examples and some information. The ‘A’ stem logo of our Amphora matches the second pipe in the panel below. The bankruptcy noted in 2012 did not spell the end of the Gubels operation. The company reorganized and continues to sell pipes at their Big Ben site (Webwinkel – bigben). What is interesting to me is that when one searches ‘Amphora’ on the internet, what one will find are the tobaccos produced with the Amphora name. The Pipedia article above commented that Amphora pipes were of a higher quality and produced mainly to bring attention to the tobacco bearing the same name. Also, one cannot find Amphora pipes so readily, which most likely indicates that they are no longer produced. A quick look at the Gubels Big-Ben website will confirm that Amphora is no longer offered in the pipe lineup of Gubels. It is possible that the Amphora line ended with the 2012 shake up, but this is only a guess and not confirmed by anything I’ve found.

Pipephil.eu also has a panel devoted to Amphora pipes with examples and some information. The ‘A’ stem logo of our Amphora matches the second pipe in the panel below. The bankruptcy noted in 2012 did not spell the end of the Gubels operation. The company reorganized and continues to sell pipes at their Big Ben site (Webwinkel – bigben). What is interesting to me is that when one searches ‘Amphora’ on the internet, what one will find are the tobaccos produced with the Amphora name. The Pipedia article above commented that Amphora pipes were of a higher quality and produced mainly to bring attention to the tobacco bearing the same name. Also, one cannot find Amphora pipes so readily, which most likely indicates that they are no longer produced. A quick look at the Gubels Big-Ben website will confirm that Amphora is no longer offered in the pipe lineup of Gubels. It is possible that the Amphora line ended with the 2012 shake up, but this is only a guess and not confirmed by anything I’ve found. With a renewed understanding of the Amphora story, it’s time to take a closer look at the Blasted Pickaxe. The chamber has a moderate layer of cake which needs to be cleaned, allowing fresh briar to emerge and a new cake developed.

With a renewed understanding of the Amphora story, it’s time to take a closer look at the Blasted Pickaxe. The chamber has a moderate layer of cake which needs to be cleaned, allowing fresh briar to emerge and a new cake developed. The rim also has a thick crust of lava flow which will be cleaned.

The rim also has a thick crust of lava flow which will be cleaned. The stummel is a very nice, blasted grain pattern and I see no fills, just usual grime.

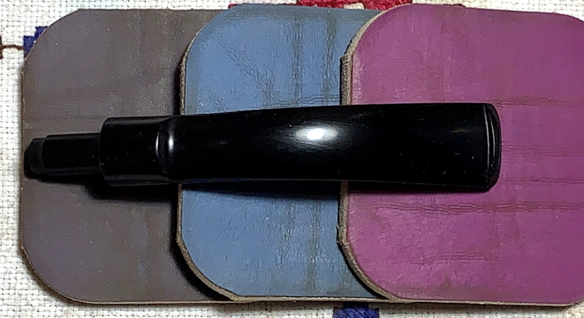

The stummel is a very nice, blasted grain pattern and I see no fills, just usual grime. The vulcanite stem shows some oxidation with a couple of tooth compressions on the upper bit and minor chatter on the lower bit.

The vulcanite stem shows some oxidation with a couple of tooth compressions on the upper bit and minor chatter on the lower bit. To begin the restoration, the stem airway is cleaned with pipe cleaners moistened with isopropyl 99% alcohol.

To begin the restoration, the stem airway is cleaned with pipe cleaners moistened with isopropyl 99% alcohol. The minor oxidation is addressed by a soak of Briarville’s Pipe Stem Oxidation Remover. A pipe cleaner is inserted into the airway to help in retrieving the stem. The soak lasts for a few hours.

The minor oxidation is addressed by a soak of Briarville’s Pipe Stem Oxidation Remover. A pipe cleaner is inserted into the airway to help in retrieving the stem. The soak lasts for a few hours. With the stem soaking, attention is turned to the stummel. First, the chamber is reamed with the Pipnet Reaming Kit. I discovered very quickly that the canted cylindrical Pickaxe chamber angled too severely for the smallest straight Pipnet blade. The Kleen Reem Pipe Tool was used instead with its expanding blade arms which are able to expand with the angle of the chamber.

With the stem soaking, attention is turned to the stummel. First, the chamber is reamed with the Pipnet Reaming Kit. I discovered very quickly that the canted cylindrical Pickaxe chamber angled too severely for the smallest straight Pipnet blade. The Kleen Reem Pipe Tool was used instead with its expanding blade arms which are able to expand with the angle of the chamber. The Savinelli Fitsall Tool is used next to scrape the chamber walls further then it is sanded using 220 paper wrapped around the dowel rod.

The Savinelli Fitsall Tool is used next to scrape the chamber walls further then it is sanded using 220 paper wrapped around the dowel rod. The entire set of tools are shown along with the pile of carbon removed from the chamber. After a quick inspection of the chamber healthy briar is seen with no heating issues visible.

The entire set of tools are shown along with the pile of carbon removed from the chamber. After a quick inspection of the chamber healthy briar is seen with no heating issues visible. Moving next to the external briar, the rim is covered by a thick crust of lava flow and normal grime on the surface.

Moving next to the external briar, the rim is covered by a thick crust of lava flow and normal grime on the surface. Undiluted Murphy Oil Soap is used to scrub the briar surface with a cotton pad. The rim is also scraped carefully with the edge of the Savinelli Fitsall Tool.

Undiluted Murphy Oil Soap is used to scrub the briar surface with a cotton pad. The rim is also scraped carefully with the edge of the Savinelli Fitsall Tool. A brass wire brush is also used to clean the rim. Brass is softer and is less invasive to the briar but adds muscle to the cleaning process.

A brass wire brush is also used to clean the rim. Brass is softer and is less invasive to the briar but adds muscle to the cleaning process. Next, the stummel is taken to the utility sink and using warm water, shank brushes, and anti-oil liquid dishwashing soap, the internals are scrubbed. Afterwards, the stummel is thoroughly rinsed and returned to the worktable.

Next, the stummel is taken to the utility sink and using warm water, shank brushes, and anti-oil liquid dishwashing soap, the internals are scrubbed. Afterwards, the stummel is thoroughly rinsed and returned to the worktable. The internal cleaning continues with cotton buds, pipe cleaners with isopropyl 99% alcohol. The mortise is also scraped with a small dental spoon to remove the tars and oils. I move on when the cleaners and buds emerge lighter.

The internal cleaning continues with cotton buds, pipe cleaners with isopropyl 99% alcohol. The mortise is also scraped with a small dental spoon to remove the tars and oils. I move on when the cleaners and buds emerge lighter. With the stummel’s basic cleaning completed, attention goes back to the stem which has been in a soak of Briarville’s Pipe Stem Oxidation Remover. The stem is fished out and a cotton cloth is used to rub off the oxidation that was raised during the soaking process. Pipe cleaners and isopropyl 99% clean the stem airway of the Briarville fluid.

With the stummel’s basic cleaning completed, attention goes back to the stem which has been in a soak of Briarville’s Pipe Stem Oxidation Remover. The stem is fished out and a cotton cloth is used to rub off the oxidation that was raised during the soaking process. Pipe cleaners and isopropyl 99% clean the stem airway of the Briarville fluid. Looking at the bit, a small bite compression is visible on the upper bit. There is also very little tooth chatter on the bit.

Looking at the bit, a small bite compression is visible on the upper bit. There is also very little tooth chatter on the bit. To minimize the small bite compression on the upper bit the heating method is used. A Bic lighter flame paints the upper bit warming the vulcanite rubber. The heat causes the vulcanite to expand helping the compression to be erased or minimized. This time, the compression does not change much, but simple sanding should erase it.

To minimize the small bite compression on the upper bit the heating method is used. A Bic lighter flame paints the upper bit warming the vulcanite rubber. The heat causes the vulcanite to expand helping the compression to be erased or minimized. This time, the compression does not change much, but simple sanding should erase it. The lower stem up to the saddle is sanded with 320 grit paper – upper and lower.

The lower stem up to the saddle is sanded with 320 grit paper – upper and lower. Next, the lower stem is wet sanded with 600 grit paper and this is followed by applying 0000 grade steel wool.

Next, the lower stem is wet sanded with 600 grit paper and this is followed by applying 0000 grade steel wool. Moving toward the polishing phase, the stem is sanded with micromesh pads. Between each pad Obsidian Oil is applied to the stem to condition the vulcanite and to guard against future oxidation. First, pads 1500, 1800 and 2400 are applied, then 3200, 3600, 4000 and finally, 6000, 8000 and 12000.

Moving toward the polishing phase, the stem is sanded with micromesh pads. Between each pad Obsidian Oil is applied to the stem to condition the vulcanite and to guard against future oxidation. First, pads 1500, 1800 and 2400 are applied, then 3200, 3600, 4000 and finally, 6000, 8000 and 12000.

Turning again to the stummel, after the cleaning, there are patches of where the finish has worn off on the surface and on the edge of the rim. The following pictures show these areas.

Turning again to the stummel, after the cleaning, there are patches of where the finish has worn off on the surface and on the edge of the rim. The following pictures show these areas.

The surface needs an application of dye to even out the hues of the worn patches. First, the surface is wipe with acetone to help prepare for the new dye application. The goal is not to remove all the old finish – this is not necessary.

The surface needs an application of dye to even out the hues of the worn patches. First, the surface is wipe with acetone to help prepare for the new dye application. The goal is not to remove all the old finish – this is not necessary. Next, Fiebing’s Tan Leather Dye is applied to the surface with a folded pipe cleaner. The dye is applied thoroughly over the surface and a second round is done to make sure the coverage is complete. After application, the stummel is set aside to allow the new dye to settle in.

Next, Fiebing’s Tan Leather Dye is applied to the surface with a folded pipe cleaner. The dye is applied thoroughly over the surface and a second round is done to make sure the coverage is complete. After application, the stummel is set aside to allow the new dye to settle in. After the stummel rested for a period, to help prevent the leeching of the new dye, the stummel is heated with the hot air gun to emulate when the pipe is first put into service. New dye can leech off onto the steward’s hand when the bowl heats up. Heating the bowl and then wiping it with a cloth helps to remove this excess dye to reduce the possibility of the dye leeching.

After the stummel rested for a period, to help prevent the leeching of the new dye, the stummel is heated with the hot air gun to emulate when the pipe is first put into service. New dye can leech off onto the steward’s hand when the bowl heats up. Heating the bowl and then wiping it with a cloth helps to remove this excess dye to reduce the possibility of the dye leeching. Next, Mark Hoover’s ‘Before & After’ Restoration Balm (www.Lbepen.com) is applied to the stummel to help bring out the hues and condition the briar. Some Balm is placed on the finger and worked into the briar surface. After applied, the stummel is set aside to allow the Balm to be absorbed.

Next, Mark Hoover’s ‘Before & After’ Restoration Balm (www.Lbepen.com) is applied to the stummel to help bring out the hues and condition the briar. Some Balm is placed on the finger and worked into the briar surface. After applied, the stummel is set aside to allow the Balm to be absorbed. The excess Balm is next wiped/buffed off with a dedicated microfiber cloth.

The excess Balm is next wiped/buffed off with a dedicated microfiber cloth. Next, Blue Diamond compound, a fine abrasive, is applied to the stem alone. It’s not applied to the stummel because the blasted surface would get fouled up with the compound dust and need to be cleaned again…not the direction we need to go. After a dedicated cotton cloth wheel is mounted on the rotary tool, the compound is applied to the stem at about 40% full power.

Next, Blue Diamond compound, a fine abrasive, is applied to the stem alone. It’s not applied to the stummel because the blasted surface would get fouled up with the compound dust and need to be cleaned again…not the direction we need to go. After a dedicated cotton cloth wheel is mounted on the rotary tool, the compound is applied to the stem at about 40% full power. To remove the compound dust, a felt cloth is used to wipe the stem.

To remove the compound dust, a felt cloth is used to wipe the stem. One more mini project for the stem. The Amphora stem logo needs refreshing. All the original paint came off during the deoxidation soak.

One more mini project for the stem. The Amphora stem logo needs refreshing. All the original paint came off during the deoxidation soak. White acrylic paint is used to cover the logo.

White acrylic paint is used to cover the logo. The wet paint is then blotted dry with a cotton pad.

The wet paint is then blotted dry with a cotton pad. The flat edge of a toothpick is next gently rubbed over the logo removing excess paint. The toothpick point is also used to fine tune the removal. This Amphora logo was a challenge with the fine lines around the up-raised areas. Unfortunately, the finished refresh is not as crisp as the original stamping. Down the road, the new steward may need to refresh the logo again with acrylic paint.

The flat edge of a toothpick is next gently rubbed over the logo removing excess paint. The toothpick point is also used to fine tune the removal. This Amphora logo was a challenge with the fine lines around the up-raised areas. Unfortunately, the finished refresh is not as crisp as the original stamping. Down the road, the new steward may need to refresh the logo again with acrylic paint. The last step is to apply carnauba wax to stem and stummel. With another dedicated cotton cloth buffing wheel mounted with the speed remaining at about 40% full power, the wax is applied. Following the application of wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove excess wax and to raise the shine.

The last step is to apply carnauba wax to stem and stummel. With another dedicated cotton cloth buffing wheel mounted with the speed remaining at about 40% full power, the wax is applied. Following the application of wax, the pipe is given a rigorous hand buffing with a microfiber cloth to remove excess wax and to raise the shine. This is a sharp looking pipe. What stands out about this Amphora X-tra Pickaxe is the subtle blasted finish and the unique Pickaxe shape. It is a light weighted pipe and could easily be used hands free with a bit guard – my preference 😊. The blasted finish provides a 3-D view of the grain patterns which is nice. Bill commissioned this Amphora and will have the first opportunity to claim him from the Pipe Store benefiting the Daughters of Bulgaria, now called Spring of Hope. Thanks for joining me!

This is a sharp looking pipe. What stands out about this Amphora X-tra Pickaxe is the subtle blasted finish and the unique Pickaxe shape. It is a light weighted pipe and could easily be used hands free with a bit guard – my preference 😊. The blasted finish provides a 3-D view of the grain patterns which is nice. Bill commissioned this Amphora and will have the first opportunity to claim him from the Pipe Store benefiting the Daughters of Bulgaria, now called Spring of Hope. Thanks for joining me!

CONGRATULATIONS FOR SUCH PROFESSIONAL WORK.👍

The difference between Before and After is like – NIGHT&DAY.

LikeLike

Thanks!

LikeLike