The Blasted Cherrywood now on the worktable came to me from a generous pipeman who donated it along with 9 others to make a very attractive Lot of 10 – now waiting in “Help Me!” Basket 2 for pipemen and women to commission. This pipeman has commissioned several pipes and I’ve had the privilege of meeting him upon his visit to the Denver area. We enjoyed a bowl or two at Edward’s Pipe & Tobacco (Edwards Pipe & Tobacco) and I look forward to being able to share a bowl again! The Cherrywood now on the worktable is on the right center in the picture below. Along with the generosity of one pipeman, I also appreciate the PATIENCE of another. Pipeman Gary from Four Oaks in the great state of North Carolina has commissioned MANY pipes from The Pipe Steward benefiting the Daughters of Bulgaria, now called, Spring of Hope. My wife and I co-founded this ministry when we lived in Bulgaria, and it continues today helping those in need. Gary’s opportunity to grow in patience was caused by my wife and I’s love of travel.

Along with the generosity of one pipeman, I also appreciate the PATIENCE of another. Pipeman Gary from Four Oaks in the great state of North Carolina has commissioned MANY pipes from The Pipe Steward benefiting the Daughters of Bulgaria, now called, Spring of Hope. My wife and I co-founded this ministry when we lived in Bulgaria, and it continues today helping those in need. Gary’s opportunity to grow in patience was caused by my wife and I’s love of travel.

After living in Europe for 33 years (and just retiring at the beginning of this month😊) we find it difficult to stay in one spot for long. We have a small travel trailer that serves us well. We just returned from camping in Ouray, Colorado, and enjoyed the beauty of the mountains and as well as watching the Rodeo in nearby Ridgeway. One of the most enjoyable times was spent visiting with former colleagues from our time serving together in Ukraine – Mel and Martha who live in nearby Montrose, Colorado. They came over to our camp where we had dinner together (grilled brats!) and then enjoyed the evening around the fire pit where Mel and I shared a bowl. Mel is on the left in the picture below with his 10-gallon hat reflecting nicely in the firelight!

After living in Europe for 33 years (and just retiring at the beginning of this month😊) we find it difficult to stay in one spot for long. We have a small travel trailer that serves us well. We just returned from camping in Ouray, Colorado, and enjoyed the beauty of the mountains and as well as watching the Rodeo in nearby Ridgeway. One of the most enjoyable times was spent visiting with former colleagues from our time serving together in Ukraine – Mel and Martha who live in nearby Montrose, Colorado. They came over to our camp where we had dinner together (grilled brats!) and then enjoyed the evening around the fire pit where Mel and I shared a bowl. Mel is on the left in the picture below with his 10-gallon hat reflecting nicely in the firelight! We had the privilege of visiting Mel and Martha in Kyiv, Ukraine, in September 2021, on a visit that was to plan our return to Ukraine after serving there in the 1990s and early 2000s. This visit was on the tail end of a trip where I chronicled my pipe picking adventures in Bulgaria and Ukraine (A Memorable Pipe Picking Adventure from Colorado to Bulgaria and Ukraine ). While in Kyiv with Mel and Martha, Mel and I took the time to share a bowl in a beautiful park in Kyiv that is now in a war zone. The picture below captured that visit and bowl – and yes, I know my hat is on crooked! Unfortunately, the following February changed our plans when Russia’s unlawful and unprovoked attack happened, escalating the war of aggression which began in 2014 with Russia’s unlawful seizure of Crimea.

We had the privilege of visiting Mel and Martha in Kyiv, Ukraine, in September 2021, on a visit that was to plan our return to Ukraine after serving there in the 1990s and early 2000s. This visit was on the tail end of a trip where I chronicled my pipe picking adventures in Bulgaria and Ukraine (A Memorable Pipe Picking Adventure from Colorado to Bulgaria and Ukraine ). While in Kyiv with Mel and Martha, Mel and I took the time to share a bowl in a beautiful park in Kyiv that is now in a war zone. The picture below captured that visit and bowl – and yes, I know my hat is on crooked! Unfortunately, the following February changed our plans when Russia’s unlawful and unprovoked attack happened, escalating the war of aggression which began in 2014 with Russia’s unlawful seizure of Crimea. Gary’s newest commission is an attractive Cherrywood which is now on the table – thanks for your patience, Gary! Here are pictures of the Cherrywood.

Gary’s newest commission is an attractive Cherrywood which is now on the table – thanks for your patience, Gary! Here are pictures of the Cherrywood.

The nomenclature is interesting. Stamped on the smooth briar heel of the Cherrywood is initially thin, DRUCQUER&SON [over] BERKELEY. Below the primary stamping appears to be a carving which at this point appears to have been chiseled by a former steward. Chiseled is: 3-15-79 [over] Portland.

The nomenclature is interesting. Stamped on the smooth briar heel of the Cherrywood is initially thin, DRUCQUER&SON [over] BERKELEY. Below the primary stamping appears to be a carving which at this point appears to have been chiseled by a former steward. Chiseled is: 3-15-79 [over] Portland. The band is stamped, STERLING which means that the silver has a purity of .925. Here is what Physical Gold (Silver Standards – The Fineness And Purity Of Silver Explained) says about it.

The band is stamped, STERLING which means that the silver has a purity of .925. Here is what Physical Gold (Silver Standards – The Fineness And Purity Of Silver Explained) says about it.

Sterling silver has a purity of 92.5%, meaning it contains 925 parts pure silver per 1,000 parts of the alloy. The remaining 7.5% is typically made up of other metals—most commonly copper—to enhance durability and strength. To find out more about the Drucquer & Son Berkeley name, Pipedia was the first stop (Drucquer & Sons Ltd.) I find there information about a ‘Dracquer & Sons’ – plural ‘sons’ not singular:

To find out more about the Drucquer & Son Berkeley name, Pipedia was the first stop (Drucquer & Sons Ltd.) I find there information about a ‘Dracquer & Sons’ – plural ‘sons’ not singular:

From a tobacco catalog associated with Drucquer & Sons Ltd shops in Berkeley and Oakland, California:

“DRUCQUER’S pipe shop was founded by John Drucquer in London in 1841. At that time, he could have had no idea of how his small enterprise would evolve. As the business was tended and knowledgeable smokers in the London of that day became aware of the quality of Drucquer tobaccos, his shop grew to be a renowned establishment, second to none. All manner of folk came in to browse, fill their pipes from the dozens of jars and relax in the very special atmosphere of a tobacconist’s shop.”

The Pipedia article also included a link to a Drucquer_&_Sons_Ltd. Catalog (c. 1970) from the Tobacconists of the same name in Berkeley and Oakland California. The catalog has a picture of the shop on the back page dated 1938. Here are the first and last pages of the catalog shown in the Pipedia article.

I enjoy looking through period catalogs and this one includes great descriptions of the tobacco they blended. It also includes ‘A Brief History of Drucquer & Sons, Ltd. which finds the origins of the shop in 1841 in London, England. Here are the pages of the catalog describing this history:

I enjoy looking through period catalogs and this one includes great descriptions of the tobacco they blended. It also includes ‘A Brief History of Drucquer & Sons, Ltd. which finds the origins of the shop in 1841 in London, England. Here are the pages of the catalog describing this history:

This accounting provides some dates that are helpful to understand the story. The tobacconist shop was founded by John Drucquer in 1841 in London, England, and in 1928, his grandson John Drucquer III moves the operation not only across the pond but to the far western USA – to Berkeley, California. The catalog history also recounts what they describe as the birth of the tobacco mail order practice when they received a request in 1934 for tobacco from Richard Black who was in Antarctica (See ‘Mackay Radio Radiogram in the picture above)!

This accounting provides some dates that are helpful to understand the story. The tobacconist shop was founded by John Drucquer in 1841 in London, England, and in 1928, his grandson John Drucquer III moves the operation not only across the pond but to the far western USA – to Berkeley, California. The catalog history also recounts what they describe as the birth of the tobacco mail order practice when they received a request in 1934 for tobacco from Richard Black who was in Antarctica (See ‘Mackay Radio Radiogram in the picture above)!

The question that piques my mind now is this tobacconist still in business in California? I did a quick Google Maps search for the two California addresses in Berkeley and Oakland given in the catalog above and discovered that these addresses no longer belong to the Drucquer & Sons shops. Searching further in the Pipesmagazine.com (Search results for query: Drucquer & Sons :: Pipe Smokers Forums of PipesMagazine.com) I discover that Drucquer & Sons tobacco blends continue to be produced and greatly appreciated. It wasn’t until I searched for information at SmokingPipes.com that I struck gold. Chuck Stanion wrote a helpful article filling in the gaps about the Drucquer & Sons story. I include it here because it completes well what the Pipedia article misses(About Drucquer & Sons Pipe Tobacco | Smokingpipes.com):

The Influential Drucquer & Sons, Ltd

The Influential Drucquer & Sons, Ltd

Drucquer & Sons was a place where pipe enthusiasts worked or gathered, enthusiasts who loved tobacco, like pipe enthusiasts everywhere. The famous tobacconist shop, however, has taken on a mythology of its own and is spoken of with respect and admiration. And why not? It’s natural to look back in time at the seemingly insignificant and retrospectively clothe it in legend, especially when it turns out to be as influential and important as Drucquer & Sons.

We’re almost required to think in terms of legend, given how little is known about the company, especially its early history. Founded in 1841 in London by John Drucquer, it evidently did well enough to maintain a good business for generations. A Drucquer catalog from the 1970s mentions that Charles Dickens at least once bought pipes in that London shop.

We can infer that many famous people living in and passing through London must have visited the tobacco shop, but no records have survived. We know only that the company was moved to Berkeley, California, from London, in 1924 by John Drucquer III, whose two sons sold the store to Robert Rex in 1964. Rex had been working at the shop for two years before purchasing it. That’s usually about how long it takes for someone to realize they want a long-term relationship with pipe tobacco.

Rex sold the shop in 1982 and became a winemaker, which is more closely related to tobacco blending than most realize. There were a couple of other owners afterward, but the shop diminished and closed around 1990. The era of Robert Rex, however, is most interesting.

At that time, most of the shop’s employees were graduate students from Berkeley who were interested in tobacco. We know that because Greg Pease, of G.L. Pease Tobacco, was one of the students working there. “I walked in,” says Greg, “and basically never left.” He’d been spending so much time in the shop, and had started helping out so much, that Robert Rex finally hired him. That’s where Greg Pease first experienced tobacco blending.

It was an intellectually rich environment, and we experienced a profound camaraderie, all of us passionate about what we were doing. – Greg Pease

Robert Rex was ahead of his time, bringing chemistry to tobacco blending and developing techniques for aging tobacco, and his blends were popular all over the world. Greg says he received his pay in pipes, which was his preference. “I was the only student walking around campus smoking Dunhills and Charatans,” he says.

The unique atmosphere of the place, says Greg, was what made it such an incredible shop. “It was an intellectually rich environment,” he says, “and we experienced a profound camaraderie, all of us passionate about what we were doing.”

Drucquer & Sons is where Greg learned to restore pipes, but the tobacco is what enthralled him. It wasn’t just tobacco to him; it seemed to take on a texture and  redolence of old-world tradition and quality, and its transformation from mere components to a balanced blend transfixed him. That experience was obviously life altering; today he’s among the most respected tobacco blenders in the world.

redolence of old-world tradition and quality, and its transformation from mere components to a balanced blend transfixed him. That experience was obviously life altering; today he’s among the most respected tobacco blenders in the world.

When Greg Pease reconstructed the Drucquer & Sons tobaccos that are made today, he did so from memory. Though it had been decades, he remembered most of the recipes, forgetting and reconstructing some of the details that he needed to figure out again, but achieving remarkable success. “I’ve had mail from people, for example, saying that the new Inns of Court is exactly like it was. Inns of Court is a special tobacco; it appeals more to me now than it did when I was young, because I’m more aware of nuance.”

It was the aroma, though, that perhaps most confirmed he had gotten these tobaccos right. “They triggered memories just like the old days,” he says. Like a key fitting a lock, the aromas were so accurate that they transported him to his youth in the bustle of one of the most influential tobacco shops ever to open doors, where he first plunged his hands into pungent tobacco.

…Inns of Court is a special tobacco; it appeals more to me now than it did when I was young, because I’m more aware of nuance. – Greg Pease

Drucquer & Sons made an indelible imprint in the history of pipe tobacco. Unfortunately, it’s another historic shop that we can no longer visit in person. But we can still appreciate it in our imaginations as we smoke tobaccos originating in the fabled shop, and we may see ourselves enveloped in lively conversation regarding the aging qualities of different tobaccos, or the proportions necessary for balance, at a time when such conversation was truly pioneering. We may even feel the waves of influence that seeded such tobacco companies as G.L. Pease and discern the aromas of the old tobaccos wafting through that shop long ago and, thanks to their resurrection, into our own pipes today.

Stanion’s article helps to bridge the Drucquer & Sons transition from a tobacconist shop to a premium name in tobaccos today. I personally was not aware of the Greg Pease story whose passion for tobacco blending was born as a student at Berkeley. Because of my own appreciation for GL Pease’s Westminster blend – one of my favorites, I’m interested in exploring the Drucquer & Sons’ blends that Greg Pease has reconstructed from his time as an ‘pipe paid’ employee of the Druquer & Sons Tobacconist.

In my research I discovered that Chuck Stanion has written other articles describing the Greg Pease story. While going down this trail goes beyond the scope of this Drucquer & Sons Cherrywood write up, I’ll include this bit of information in another Stanion piece at Smoking Pipes (G.L. Pease: The Man Behind the Blends | Smokingpipes.com) because it drills in further on Pease’s experience at the Drucquer & Sons Shop in Berkeley:

“When I walked into Drucquer’s, I finally experienced real tobacco. I mean tobacco that didn’t smell like my gram’s potpourri, that wasn’t sticky to the touch, or translucent from the generous application of what I later learned was [the food-grade humectant] propylene glycol. It was a turning point, and I quickly learned to love the more traditional styles of tobaccos. At the time, all those blends we now think of as ‘classic’ and ‘vintage’ were easily found, and I explored just about every tinned blend on the shelves in addition to those produced in house. Those classic tobaccos really attracted me — the Four Squares, the Sullivan & Powells, the Sobranies, the Dunhills, the State Expresses, and of course, the Nuns.”

“When I walked into Drucquer’s, I finally experienced real tobacco. I mean tobacco that didn’t smell like my gram’s potpourri, that wasn’t sticky to the touch, or translucent from the generous application of what I later learned was [the food-grade humectant] propylene glycol. It was a turning point, and I quickly learned to love the more traditional styles of tobaccos. At the time, all those blends we now think of as ‘classic’ and ‘vintage’ were easily found, and I explored just about every tinned blend on the shelves in addition to those produced in house. Those classic tobaccos really attracted me — the Four Squares, the Sullivan & Powells, the Sobranies, the Dunhills, the State Expresses, and of course, the Nuns.”

It was at Drucquer’s that Greg discovered the advantages of aging tobacco. “And I’ve been hoarding — strike that — cellaring ever since. As with wines, aging tobaccos can make a great blend greater, enhancing its natural sweetness, increasing its complexity, offering new layers and new dimensions to the smoke that are only hinted at by the fresh product.” He learned that aging works well, though, only when the tobacco is superior to begin with “A friend of mine in the wine world told me, ‘An aged wine is magnificent if it’s good to begin with. Age a bottle of piss, and you end up with a bottle of old piss.'”

But it was the atmosphere of the tobacco shop that particularly appealed to Greg. He was a college student and a rock & roll musician, long haired and inexperienced and young, but the traditional ambiance inspired and gratified him. “It was dark and smoky and paneled with lots of dark wood and glass and pipes everywhere, and a beautiful humidor. The people working there were knowledgeable and were clearly there because they loved what they were doing. I felt a kinship with the people, and also this feeling of belonging. It just felt right. If I close my eyes, I can still see the entrance. I can experience walking through those doors. Yeah, it was beautiful, and I feel a lot of melancholy that it’s gone.”

Greg discovered what real pipe smoking was all about when he visited the Drucquer & Sons tobacco shop just a block off campus.

Greg likes to say that after he first walked into Drucquer’s, he never left. “It was full of people who absolutely loved pipes, tobacco, cigars. It was a real place for like-minded folk to congregate, and that’s where I really started learning about tobacco, about the fact that it doesn’t have to be translucent with additives to be good. I learned how to fill a pipe for the first time the correct way, and started my long love affair with Latakia, and pretty much spent as much time there as I could. All my spare time was spent in that shop.”

If one wants to drill down further, I also enjoyed reading Chuck Stansion’s June 2024 article, ‘What’s Happening Lately with Greg Pease’ (G.L. Pease Tobaccos | Gregory Pease).

Looking back at our pipe, what’s interesting is that the date inscription on our Cherrywood helps us to place it in the Drucquer & Sons story. If we decide that the date and location inscribed was the work of this Cherrywood’s first steward, it would place the pipe during the Robert Rex ownership beginning in 1964 until he sold in 1982. We do not know which pipe manufacturer produced this pipe with the Drucquer & Sons name stamped on it, but the date of 1979 gives us the latest bracket – at least 46 years ago this Cherrywood went into service in the great Northwest – Portland, Oregon, California’s neighbor to the north.

Only one mystery remains. Everywhere that I’ve seen references to Drucquer & Sons in my research ‘son’ is plural. Our pipe has a singular ‘son’. I suppose it’s possible that the ‘s’ has faded along with the beginning of the stamping. We’ll go with that😊. With a newfound appreciation for the Drucquer & Sons name and the G.E. Peace connection, it’s time for a closer look at the blasted Cherrywood. A Cherrywood is a Poker that has a bent stem. Here’s Bill Burney’s description from Pipedia (Cherrywood – Pipedia)

With a newfound appreciation for the Drucquer & Sons name and the G.E. Peace connection, it’s time for a closer look at the blasted Cherrywood. A Cherrywood is a Poker that has a bent stem. Here’s Bill Burney’s description from Pipedia (Cherrywood – Pipedia)

The bones of the pipe are in good shape. The chamber has some cake buildup but not much. The rim is darkened somewhat from lava flow. Overall, the stummel needs normal cleaning and will look great. I like the blasted finish and dark hues of this pipe.

The bones of the pipe are in good shape. The chamber has some cake buildup but not much. The rim is darkened somewhat from lava flow. Overall, the stummel needs normal cleaning and will look great. I like the blasted finish and dark hues of this pipe. The Cherrywood heel has seen better days. There are several scratches and a few cuts which I’ll try to erase without bothering the already thin nomenclature.

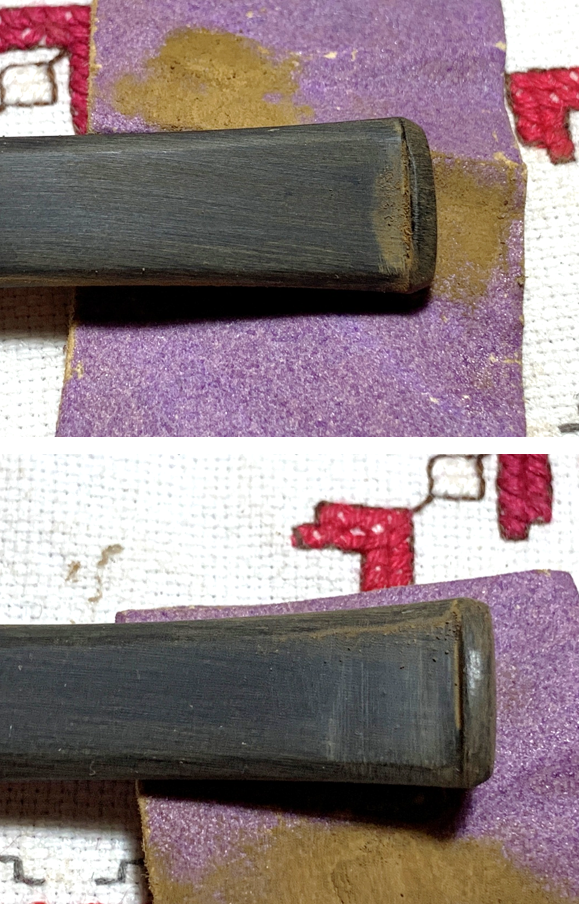

The Cherrywood heel has seen better days. There are several scratches and a few cuts which I’ll try to erase without bothering the already thin nomenclature. The stem has chatter and compressions on both upper and lower sides, but the upper bit has more damage. The button also has been compressed at places by clenching.

The stem has chatter and compressions on both upper and lower sides, but the upper bit has more damage. The button also has been compressed at places by clenching. The stem shows some oxidation especially around the saddle.

The stem shows some oxidation especially around the saddle. To begin the restoration of this Drucquer & Sons Cherrywood the stem airway is cleaned with a few pipe cleaners moistened with isopropyl 99% alcohol.

To begin the restoration of this Drucquer & Sons Cherrywood the stem airway is cleaned with a few pipe cleaners moistened with isopropyl 99% alcohol. To address the oxidation, the stem is placed in a soak with Briarville’s Pipe Stem Oxidation Remover. An inserted pipe cleaner serves as a handle for easier retrieval from the soak that will last for several hours – through the night in this case.

To address the oxidation, the stem is placed in a soak with Briarville’s Pipe Stem Oxidation Remover. An inserted pipe cleaner serves as a handle for easier retrieval from the soak that will last for several hours – through the night in this case. The chamber is next reamed using the Pipnet Reaming Kit. 3 of the 4 blades available were used to clear the cake residue.

The chamber is next reamed using the Pipnet Reaming Kit. 3 of the 4 blades available were used to clear the cake residue. Reaming is followed by scraping the chamber walls with the Savinelli Fitsall Tool.

Reaming is followed by scraping the chamber walls with the Savinelli Fitsall Tool. The final step to cleaning the chamber is sanding with 220 paper wrapped around a dowel rod.

The final step to cleaning the chamber is sanding with 220 paper wrapped around a dowel rod. The full set of tools and the pile of carbon cake is shown. A quick inspection of the chamber reveals healthy briar with no burning or heating issues.

The full set of tools and the pile of carbon cake is shown. A quick inspection of the chamber reveals healthy briar with no burning or heating issues. To clean the exterior blasted briar surface, undiluted Murphy Oil Soap is used. A cotton pad scrubs the surface, and a soft brass brush works on the rim to remove the darkened lava flow.

To clean the exterior blasted briar surface, undiluted Murphy Oil Soap is used. A cotton pad scrubs the surface, and a soft brass brush works on the rim to remove the darkened lava flow. Next, the pipe is taken to the utility sink using shank brushes with warm water and an anti-oil liquid dishwashing soap, the internals are scrubbed. Afterward, the stummel is given a thorough rinse and taken back to the worktable.

Next, the pipe is taken to the utility sink using shank brushes with warm water and an anti-oil liquid dishwashing soap, the internals are scrubbed. Afterward, the stummel is given a thorough rinse and taken back to the worktable. Next, cleaning continues on the internals using cotton buds and pipe cleaners moistened with isopropyl 99% alcohol. A small dental spoon is used to scrape the mortise walls excavating a boatload of accumulated tar and oils.

Next, cleaning continues on the internals using cotton buds and pipe cleaners moistened with isopropyl 99% alcohol. A small dental spoon is used to scrape the mortise walls excavating a boatload of accumulated tar and oils. When the buds start emerging lighter, the cleaning is called.

When the buds start emerging lighter, the cleaning is called. With the primary cleaning completed, I take a closer look at the stummel. The cleaning lightened the finish on the rim and this needs to be addressed.

With the primary cleaning completed, I take a closer look at the stummel. The cleaning lightened the finish on the rim and this needs to be addressed. A dye stick is used to darken the lightened rim. I do some testing with different hues and land on chestnut. The rim looks good and the chestnut dye stick blends nicely.

A dye stick is used to darken the lightened rim. I do some testing with different hues and land on chestnut. The rim looks good and the chestnut dye stick blends nicely. I noted earlier that there was some scratching on the heel of the Chestnut. This is normal and expected with a sitter shape. There are also some small compressions that probably resulted from being placed on a hard surface a bit too roughly.

I noted earlier that there was some scratching on the heel of the Chestnut. This is normal and expected with a sitter shape. There are also some small compressions that probably resulted from being placed on a hard surface a bit too roughly. Micromesh pads are used to clean the heel. With the first set of three pads, 1500, 1800 and 2400 grits, being more abrasive I apply around the thinning nomenclature not wanting to thin it further. With the remaining 6 pads (3200 to 12000), being finer, are applied to the entire heel. The grain came out very nicely. The arrow is pointing to the compression in the briar. I decided to leave it as a testament to its past and nod to its future serving a new steward.

Micromesh pads are used to clean the heel. With the first set of three pads, 1500, 1800 and 2400 grits, being more abrasive I apply around the thinning nomenclature not wanting to thin it further. With the remaining 6 pads (3200 to 12000), being finer, are applied to the entire heel. The grain came out very nicely. The arrow is pointing to the compression in the briar. I decided to leave it as a testament to its past and nod to its future serving a new steward. To condition the briar and to bring out the natural hues, Mark Hoover’s ‘Before & After’ Restoration Balm is applied. After putting some on the fingers, the Balm is worked into the briar thoroughly and then set aside for about 15 minutes for the Balm to do it thing.

To condition the briar and to bring out the natural hues, Mark Hoover’s ‘Before & After’ Restoration Balm is applied. After putting some on the fingers, the Balm is worked into the briar thoroughly and then set aside for about 15 minutes for the Balm to do it thing. After a time, a dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the shine. The dedicated cloth is also used to apply a quick treatment to my personal collection because it has become saturated with the Balm. I like how the briar comes alive after the Balm treatment.

After a time, a dedicated microfiber cloth is used to wipe off the excess Balm and to buff up the shine. The dedicated cloth is also used to apply a quick treatment to my personal collection because it has become saturated with the Balm. I like how the briar comes alive after the Balm treatment. The stummel is put to the side and attention is now on the stem that has been soaking in Briarville’s Pipe Stem Oxidation Remover. I’m amazed at how thick the oxidation appears to be after taking it out of the soak.

The stummel is put to the side and attention is now on the stem that has been soaking in Briarville’s Pipe Stem Oxidation Remover. I’m amazed at how thick the oxidation appears to be after taking it out of the soak. To remove the raised oxidation, first, a cotton cloth is used to rub vigorously the stem surface to wipe away the stubborn oxidation sludge. I switch to using 0000 grade steel wool because the raised oxidation was not cooperating. To clear away the Briarville fluid, a pipe cleaner moistened with isopropyl 99% cleans the airway.

To remove the raised oxidation, first, a cotton cloth is used to rub vigorously the stem surface to wipe away the stubborn oxidation sludge. I switch to using 0000 grade steel wool because the raised oxidation was not cooperating. To clear away the Briarville fluid, a pipe cleaner moistened with isopropyl 99% cleans the airway. Looking at the upper bit, there’s a deep bite compression which still has oxidation in the pit. The lower bit also has chatter and compression on the lower bit.

Looking at the upper bit, there’s a deep bite compression which still has oxidation in the pit. The lower bit also has chatter and compression on the lower bit. To reduce the severity of compression on the upper bit, the flaming method is used. A Bic lighter paints the upper bit with the flame. As the vulcanite heats, the rubber compound expands with the compression reverting to its original shape – or hopefully, closer to it. The heating did help so that sanding only should erase it.

To reduce the severity of compression on the upper bit, the flaming method is used. A Bic lighter paints the upper bit with the flame. As the vulcanite heats, the rubber compound expands with the compression reverting to its original shape – or hopefully, closer to it. The heating did help so that sanding only should erase it. Both the upper and lower bit are sanded with 220 paper.

Both the upper and lower bit are sanded with 220 paper. The sanding with 220 grit paper expands to the entire stem with the sanding disk protecting the stem facing from shouldering.

The sanding with 220 grit paper expands to the entire stem with the sanding disk protecting the stem facing from shouldering. The 220 paper is followed by 320 grit paper.

The 220 paper is followed by 320 grit paper. Next, the stem is wet sanded using 600 grit paper and this is followed by applying 0000 grade steel wool.

Next, the stem is wet sanded using 600 grit paper and this is followed by applying 0000 grade steel wool. Micromesh pads are employed next. Between each pad a very light application of Obsidian Oil is applied to the stem to condition the stem, guard from oxidation and give the next pad better traction. Pads 1500, 1800, and 2400 are applied first followed by 3200, 3600, 4000 and then 6000, 8000, and 12000.

Micromesh pads are employed next. Between each pad a very light application of Obsidian Oil is applied to the stem to condition the stem, guard from oxidation and give the next pad better traction. Pads 1500, 1800, and 2400 are applied first followed by 3200, 3600, 4000 and then 6000, 8000, and 12000. Before continuing with the application of Blue Diamond compound, the sterling band needs to be cleaned up and polished. For this, a cotton cloth buffing wheel dedicated to metals is mounted on the rotary tool. As you can see, the buffing wheel is black from the residue produced by buffing metals with compound. For this reason, a protective strip of painters’ tape is wrapped around the shank to protect it from the black residue. With the speed set at about 40% full power, green compound is applied to the sterling band.

Before continuing with the application of Blue Diamond compound, the sterling band needs to be cleaned up and polished. For this, a cotton cloth buffing wheel dedicated to metals is mounted on the rotary tool. As you can see, the buffing wheel is black from the residue produced by buffing metals with compound. For this reason, a protective strip of painters’ tape is wrapped around the shank to protect it from the black residue. With the speed set at about 40% full power, green compound is applied to the sterling band. The picture below shows the residue from buffing the sterling with the compound. The dark residue may not be as noticeable with darker hue of this Cherrywood, but I like to keep a clean ship.

The picture below shows the residue from buffing the sterling with the compound. The dark residue may not be as noticeable with darker hue of this Cherrywood, but I like to keep a clean ship. The sterling band is buffed up to a nice shine with a microfiber cloth. I like it😊.

The sterling band is buffed up to a nice shine with a microfiber cloth. I like it😊. The stem and stummel are reunited and Blue Diamond compound is applied to the stem and only to the smooth briar heel of the stummel. The blasted surface would only get fouled up with the compound dust and I don’t want to clean that up! With a dedicated cotton cloth buffing wheel mounted on the rotary tool, the speed is at about 40% full power.

The stem and stummel are reunited and Blue Diamond compound is applied to the stem and only to the smooth briar heel of the stummel. The blasted surface would only get fouled up with the compound dust and I don’t want to clean that up! With a dedicated cotton cloth buffing wheel mounted on the rotary tool, the speed is at about 40% full power. To remove compound dust after the application of Blue Diamond, the heel and stem are cleaned up with a felt cloth.

To remove compound dust after the application of Blue Diamond, the heel and stem are cleaned up with a felt cloth. Next, carnauba wax is applied to the entire pipe except for the sterling silver band. After applying the wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine.

Next, carnauba wax is applied to the entire pipe except for the sterling silver band. After applying the wax, the pipe is given a rigorous hand buffing to remove excess wax and to raise the shine. I enjoyed immensely diving into the long history of a tobacconist shop that has disappeared – as has so many classic tobacconist shops. The story of Drucquer & Sons in 1841in London and the following century crossed over the Atlantic Ocean and continued a quality tradition in California. The tobacconist not only sold pipes, but also quality tobacco blends were created, some of which continue to be produced today recreated by G.L. Pease. The Cherrywood on the table has a classic but rustic feel with the Cherrywood shape. The dark, blasted surface resembles English pipes to me, especially Dunhill. Gary commissioned this Drucquer & Sons Cherrywood and will have the first opportunity to claim him from the Pipe Store benefitting the Daughters of Bulgaria (now called, Spring of Hope). Thanks for joining me and thank you to the generous pipeman that donated this pipe!

I enjoyed immensely diving into the long history of a tobacconist shop that has disappeared – as has so many classic tobacconist shops. The story of Drucquer & Sons in 1841in London and the following century crossed over the Atlantic Ocean and continued a quality tradition in California. The tobacconist not only sold pipes, but also quality tobacco blends were created, some of which continue to be produced today recreated by G.L. Pease. The Cherrywood on the table has a classic but rustic feel with the Cherrywood shape. The dark, blasted surface resembles English pipes to me, especially Dunhill. Gary commissioned this Drucquer & Sons Cherrywood and will have the first opportunity to claim him from the Pipe Store benefitting the Daughters of Bulgaria (now called, Spring of Hope). Thanks for joining me and thank you to the generous pipeman that donated this pipe!

Thank you for this extremely well-documented article, Dal.

LikeLike

Thanks so much, Todd! It turned out great and I enjoyed diving into the provenance on this one. 🙂

LikeLike